There are several key features to look for when selecting stainless steel insert fitting that will ensure they install easily, last longer and hold more pressure.

In this blog we are going to go over the following features and why they are beneficial.

- Lead Barb

- Consistent Wall Thickness

- Smooth Internal Surface

- Sharp Barbs / Serrations

- Corrosion Resistance

![]()

![]()

![]()

SSMA SSMAXL CSS SSHL SSHT SSEL SSTE FASS MASS

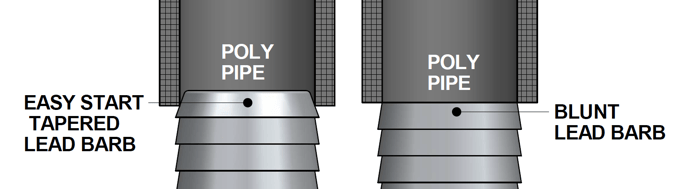

1. Lead Barb

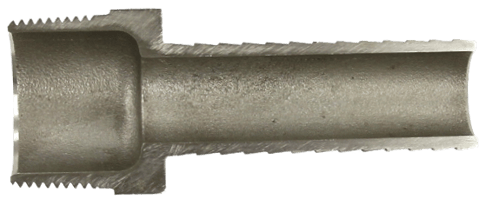

The lead barb is the first barb that enters into the poly pipe, like a leader. This does not refer to the material lead. The lead barb has more taper to reduce the diameter at the end of the fitting, it is designed to be smaller than the inside pipe diameter to ensure an easy start when inserting into poly pipe, even if the pipe is cold and slightly oval in shape, due to being stored on a coil.

In cold temperatures heating the poly pipe in hot water makes the poly pipe more pliable and easier to expand over the barbs during installation of the fitting, in warm or heated state poly pipe retracts and forms into the serrations for good sealing and pull-off resistance when secured by a quality All Stainless Steel Gear Clamp.

When selecting an insert fitting look for the special lead barb feature, for faster and easier insertion into the pipe. The above diagram illustrates a tapered lead barb versus a blunt start insert fitting. Avoid lost time and frustration, due to the difficulties, with installing blunt end fittings.

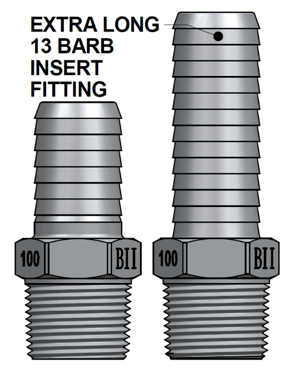

2. Sharp Serrations

The purpose of the barbs or serrations is quite simple, they allow the poly pipe to easily slide onto the fitting but harder to remove. The degree of barb sharpness determines how well they grip when a pulling force is ap plied. Sharp barbs make it virtually impossible to pull the pipe from the fitting, providing excellent blow off protection from system pressure as well as pull-off protection against pulling force such as the weight of a pump column in a submersible pump application. Additional pull-off resistance can be obtained by using an “extra-long insert”, these fittings can have up to 13 barbs providing additional grip and space for double clamping.

plied. Sharp barbs make it virtually impossible to pull the pipe from the fitting, providing excellent blow off protection from system pressure as well as pull-off protection against pulling force such as the weight of a pump column in a submersible pump application. Additional pull-off resistance can be obtained by using an “extra-long insert”, these fittings can have up to 13 barbs providing additional grip and space for double clamping.

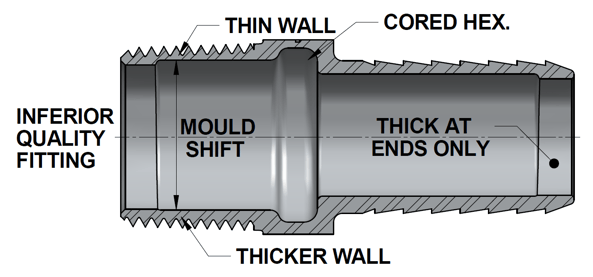

3. Consistent Wall Thickness

Many insert fittings on the market have serious inconsistencies in the wall thickness. This is often caused by mold shifting during the sand-casting process. If the mold shifts, more material ends up on one side leaving the other side with a thinner, weaker wall. Insert fittings with thicker, consistent walls, are stronger and will last longer.

The internal profile of the insert fitting is just as important as the outside. When selecting a stainless steel insert fitting look for quality insert fittings made using the investment casting process or the swaged from tube process. Both Investment casting and swagging processes provide accurate and uniform walls.

Boshart Industries is committed to quality assurance and ensures that insert fittings have a consistent wall thickness.

Wall thickness is not easily determined by weight or appearance, it may require close examination of the fittings cross section to identify inferior quality insert fitting. When selecting insert fittings there are three key problem areas to watch out for. (see diagram below)

#1 Fittings with a short thick wall section at each end. This is purposely done to cut raw material costs while giving the buyer the perception they are buying a quality heavy wall fitting. Unfortunately, the cored section between the short thick sections at each end has a much thinner wall which will reduce the longevity of the fitting.

# 2 Cored HEX causes turbulence at the recessed area, reducing the flow rates and pumping efficiency. Furthermore it weakens the fitting and can result in the fitting being deformed when tightened with pipe wrench.

#3 Mold shift due to inferior quality castings results in a thin wall section on one side and a thicker wall on the opposite side, mold shift can result in catastrophic fitting failure especially in applications where the fitting needs to support weight such as in submersible pump installations.

4. Smooth Internal Surface

As with the consistent wall thickness point, surface finish of the interior is not evident at a quick glance and often overlooked. Stainless insert fitting that are made by either the swage or investment casting process provide a smooth internal surface, reducing turbulence and friction loss as water flows through the fitting.

5. Corrosion resistance

Stainless steel insert fittings for poly (PE) pipe have excellent corrosion resistance, which will extend the life of the fittings in your system. Unlike many brass alloys, stainless steel does not contain zinc and is not affected by dezincification.

In conclusion, 304 Stainless steel alloys are consistent from one supplier to the next and are suitable for a wide range of applications. Some of these features are easier to identify visually than others. The combination of all five of these features ensures you have an excellent insert fitting that will install easily, last longer and hold up to more pressure.

Have further questions about this subject?

Head over to Boshart's Knowledge Base: technical product information, guidelines, and more.

SHARE