Industrial pitless units are not a cheap thing to install. With so many important components hidden underground it's important to cap it off with something that is tamper proof and built to last.

In this blog, we are going to explore eight features to look for in industrial well caps and why they are important features. Here are the eight features we will cover:

- Locking Feature

- Large Conduit Connection

- Stainless Steel Hardware

- Air Vent

- Grounding Terminal

- Accessory Ports

- Positioning Tabs

- Material & Finish

Locking Features

To ensure that the industrial well cap is secure and tamper proof the ability to lock it is important. With the use of cotter pins or locking pins with pad locks the well cap can't be removed by someone who doesn't have the key or code.

Large Conduit Connection

Industrial wells require industrial sized pumps, and to run one of these pumps more cables are required to be fed down to the pump. To accommodate these cables well caps that have a large conduit connection is important. A well seal and conduit adapter can be used to keep the cables organized and ensure the well cap remains vermin proof.

Stainless Steel Hardware

Having stainless steel hardware will ensure the bolts and nuts that secure the well cap together are corrosion resistant. Well caps are installed outdoors and exposed to the elements and moisture. Using corrosion resistant hardware will ensure that when it comes time to access the pump and pitless in the well, removing the well cap will not be difficult because of corroded or seized nuts & bolts.

Air Vent

Air vents allow the well to breath while also keeping them vermin proof. Well caps with a domed vent protects the screen while still allowing the well to breath. This vent can be replaced with a plug or floating ball vent for a water proof design.

Grounding Terminal

When electricity is involved it has to be grounded. Some industrial well caps come complete with a grounding terminal built right into the cap. This allows for the cables that operate the pump to be easily grounded without any extra work.

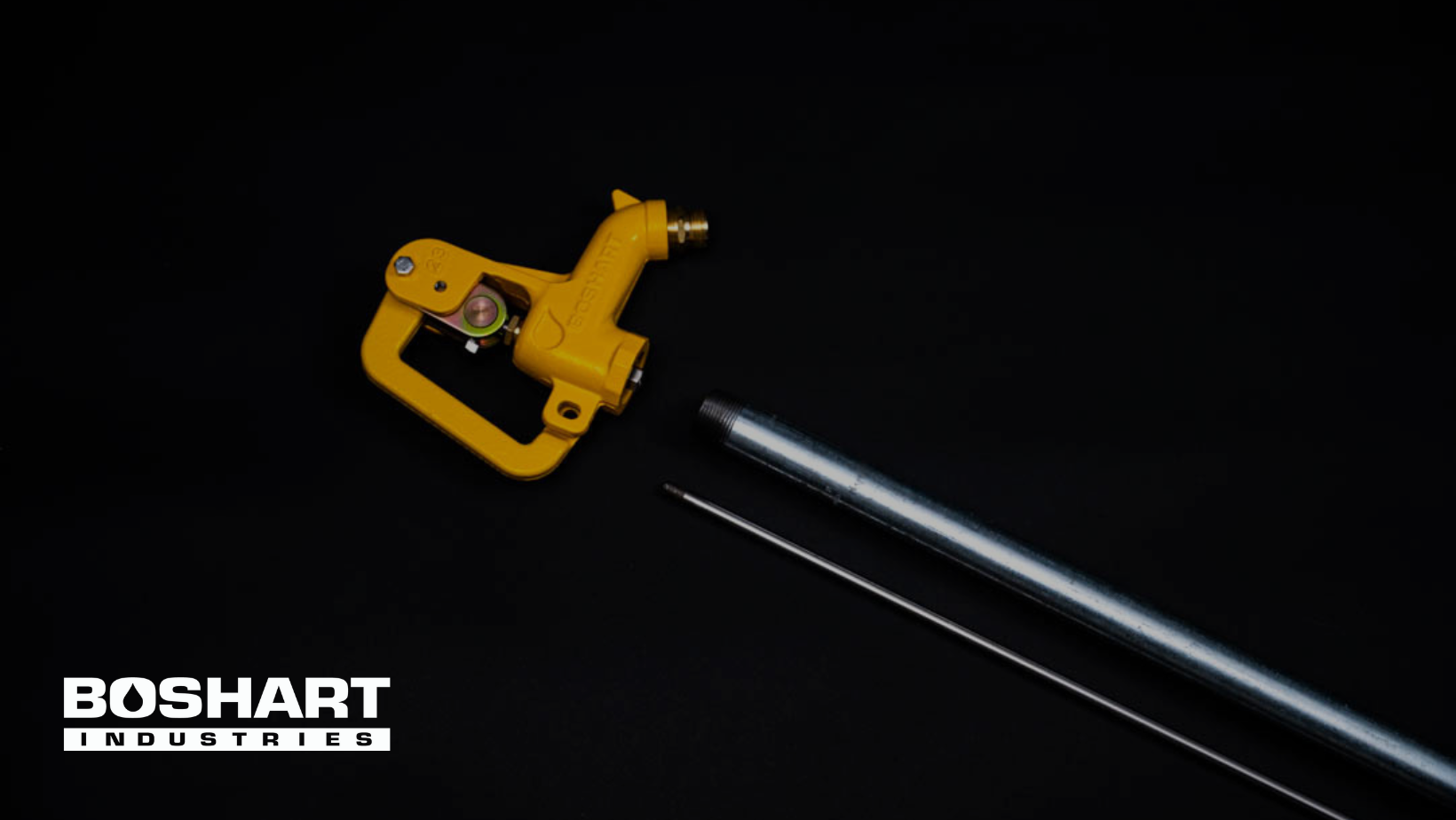

Accessory Ports

Built in accessory ports make adding accessories to the well much easier and smoother. An example of an accessory that could be added is a depth tester kit to determine how much water is in the well. Not all accessory ports will be used all the time, so well caps that come with plugs or caps for these ports is key. If they can be locked so no one can remove them is even better ensuring a tamper proof cap.

Positioning Tabs

The positioning tabs allow the lower assembly to be installed without the well cap cover. The lower assembly can be quickly slid onto the casing and the bolts tightened at the exact location. This eliminates the need to lift the whole well cap at once.

Material & Finish

When selecting a well cap, you want to make sure it is going to last. A material to look for is cast iron as it is heavy duty. Baking on powder coat paint ensures superior quality.

These eight features are key things to look for in industrial well caps. These types of well caps require more research before making a purchase. Understanding what features are available will help determine what is most important when making a selection.

Have further questions about this subject?

Head over to Boshart's Knowledge Base: technical product information, guidelines, and more.

![[Video] 4 Features to Look for in Bronze Insert Fittings](https://blog.boshart.com/hubfs/Bronze%20Insert.jpg)

SHARE