Do you have heavy sediment or large volume of scale, debris, sand, or grit needing to be removed from your water filtration system? Selecting the right mesh filter element for your sediment filter or separator starts with having a good understanding of what is on the market and what they remove from water.

Water mesh filter elements are specifically designed to remove large volumes of sediment. In this blog, we will be going over four things to consider when selecting a mesh filter element.

Housing Selection

Part of selecting an element is determining what housing you have or need. If you already have one installed, the size is listed on the inlet and outlet. When installing a new one, knowing the desired flow rate greatly helps! Check out our “What is the Typical Household Water Flow Rate” blog for more on determining flow rates.

Flow rates in sediment filters and separators have a wide flow rate overlap between sizes. For example, a 1” filter housing has a flow rate of 1-25 GPM and a 1-1/2” filter housing has a flow rate of 10-50 GPM. If your flow rate is within the range, it’s best to go with a smaller size to ensure the centrifugal force is adequate to separate the sand from the water. That would mean that if your desired flow rate is 20 GPM a 1” filter housing would be more effective.

Element Type

Elements come in two different styles, filter and separator. They both work the same way, the difference being that separators allow for more sediment to build up before it needs to be purged. Our "Understanding Sediment Filters & Separators" blog goes over the difference in more detail.

Depending on the size of the housing the filter may look different. For 1” housings the filters look the same between filters and separators whereas for a 1-1/2” and 2” housing, the filter has a shorter screened area and a stem holding the filter part up which gives room for the sediment to build up at the bottom. The image shows a filter element on the left and a separator element on the right for a 1-1/2" or 2" housing.

Mesh Material

There are two main mesh materials, polyester and stainless steel. Polyester mesh is manufactured from non-corrosive material and is ultraviolet stabilized / weather resistant. Stainless steel mesh is manufactured from 316 stainless steel and is non-corrosive and durable.

Stainless steel will hold up better to sharp sediment and particles as they won’t rip the material. In the past polyester was the more economical option but that has changed making them both very economical options.

Mesh Size

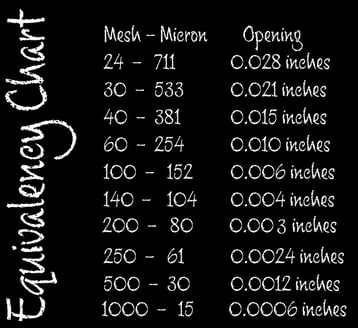

Selecting the mesh size required is determined by what needs to be removed from the water. When talking about filtration there is different terminology that defines the size of things that will be removed. The equivalency chart below shows the comparison between the different terminologies.

The opening is the size of space between material that water and particles can pass through. The number of openings in one square inch of screen is called the mesh size. The micron rating is the distance between filter media. “Water Filters – The Basics on Micron Ratings” goes over this in more detail.

The opening is the size of space between material that water and particles can pass through. The number of openings in one square inch of screen is called the mesh size. The micron rating is the distance between filter media. “Water Filters – The Basics on Micron Ratings” goes over this in more detail.

When using a sediment filter or separator as a pre-filter for other water filtration products, make sure that the mesh size is equivalent to a larger micron rating. For example if your filter is 80 micron you would want to use a mesh size of 140 or smaller.

To give you an idea of some common sizes, scale may be removed by using a 24 mesh element whereas sand is smaller and would require a mesh element with a 100 rating or even higher.

Determining the amount of sand / sediment that needs to be removed will help determine the element that is right for you. No matter which element you choose it can be removed and cleaned with a soft brush. Soaking the element in 50/50 bleach and water solution will help remove stains caused by iron, etc. Be sure to rinse the element thoroughly before it is installed again. Now you have a better understanding of what goes into choosing a water mesh filter element and what the options are.

Have further questions about this subject?

Head over to Boshart's Knowledge Base: technical product information, guidelines, and more.

SHARE