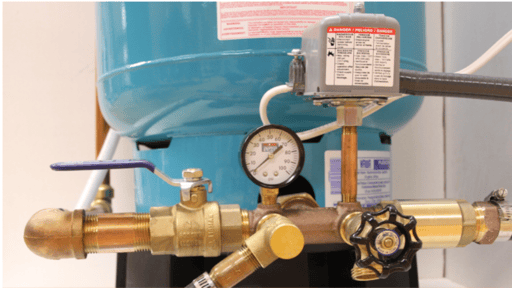

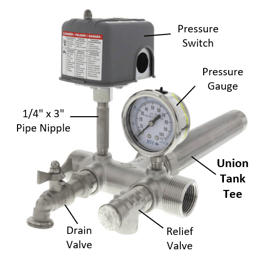

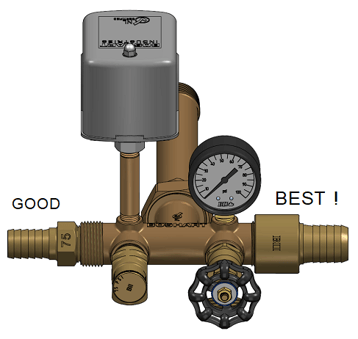

The photos below show a union type tank tees with these components installed.

In this blog post, we will discuss what the various types of tank tees, their applications and go over the different materials available.

Types of Tank Tees

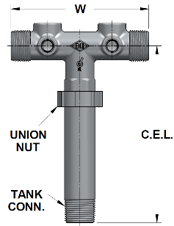

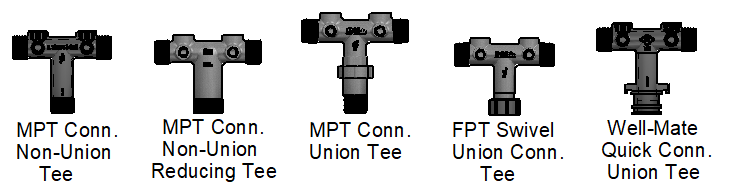

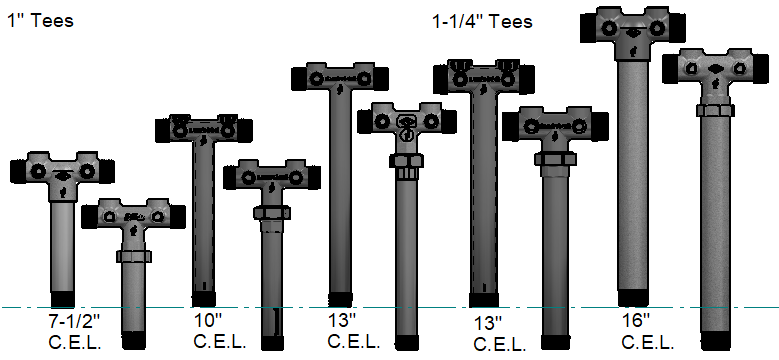

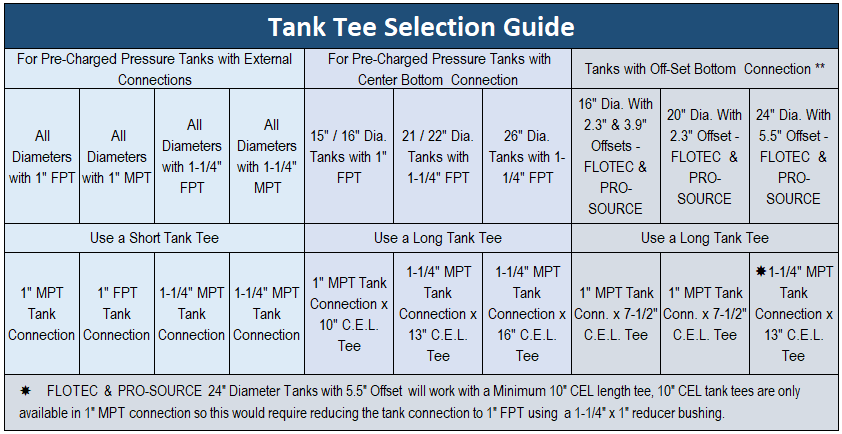

Tank tees are available in various lengths short (3”) to long (16”) to work with the connection sizes and locations on various brands of pressure tanks. The two major design types are Union and Non-union which may be referred to as solid or 1-piece tank tees. They are available in 1” and 1-¼" with male or female tank connections. Regardless tank tees are designed for connecting to any pre-charged pressure tanks. Tank tee length measurements are Center-End-Lengths (CEL)

Short Tees Tank

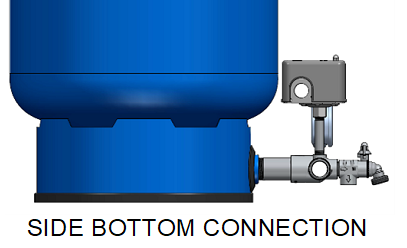

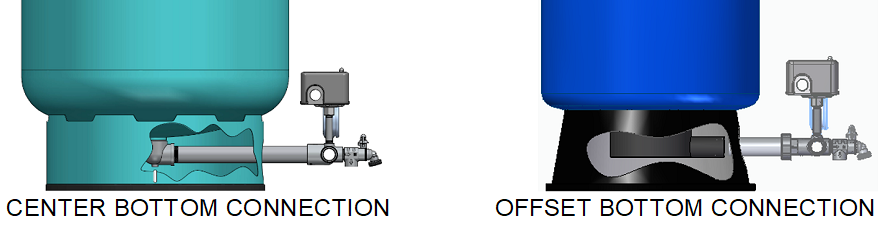

Are used on pressure tanks with the tank connection protruding through the side of the tanks base. Short tees range from 3” to 4-1/2” CEL. Short tank tees are available in several types of tank connection as shown below.

Long Tees Tank

Are used on pressure tanks with the tank connection being either at the center or offset inside the bottom of the tanks base. Long tanks tees have male NPT tank connection and are available in several lengths. Longer tank tees are required as the diameter of the pressure tank selected increases, the CEL must be sufficient to extend the tee head out far enough so that the pressure switch can threaded on or off without contacting the pressure tank.

Union vs. Non-Union Tank Tees

Union vs. Non-Union Tank Tees

The benefits of union tank tees are realized during initial installation, and significantly reduces the labor involved for tank replacement. A union type tee easily disconnects the old tank, which can be removed in minutes leaving all the line and accessory connections and wiring intact. The new tank can then be fitted with the tank tee leg from the old tank, set in position and reconnected to the tank tee head by tightening the union. Job done!

Union tees that incorporate an O-ring provide a reliable watertight seal. No need to worry about the connection leaking. It is recommended to select a quality tank tee that uses a North American standard O-ring which are readily available in the event a replacement is ever needed.

Non-union tank tees do the same job, are less money and save money on the purchase price. However, they simply do not have the same ease of installation and time saving benefits especially when a tank needs to be replaced. The added labor involved during installation or tank replacement will far exceed the initial savings on the tee.

Tank Tee Materials

Stainless Steel Tank Tees

Stainless steel tank tees more price competitive than No-Lead Bronze and are replacing bronze (red brass) tank tees since the introduction of No-Lead requirements in 2014. Typically cast from 304 stainless steel which is incredibly durable and very corrosion resistant. Although stainless tees are more expensive than brass, they do not contain zinc alleviating the problems with dezincification that can occur when using brass alloy tank tees in aggressive water conditions. Another advantage is the extremely high strength of stainless steel virtually eliminates all risk of stress cracking when threading into female connections.

replacing bronze (red brass) tank tees since the introduction of No-Lead requirements in 2014. Typically cast from 304 stainless steel which is incredibly durable and very corrosion resistant. Although stainless tees are more expensive than brass, they do not contain zinc alleviating the problems with dezincification that can occur when using brass alloy tank tees in aggressive water conditions. Another advantage is the extremely high strength of stainless steel virtually eliminates all risk of stress cracking when threading into female connections.

Brass Alloy Tank Tees

Brass tank tees are less expensive and are suited for installations in most areas. However brass alloys are not as corrosion resistant as stainless steel, therefore installations in areas where the water is highly corrosive to brass, it is recommended to upgrade to stainless steel.

are not as corrosion resistant as stainless steel, therefore installations in areas where the water is highly corrosive to brass, it is recommended to upgrade to stainless steel.

Galvanized Tank Tees

Galvanized tees are less expensive than both stainless steel and brass tank tees. Their use is typically limited to installations on galvanized pressure tanks without a bladder. Galvanized tees are selected to eliminate the risk of galvanic corrosion between dissimilar metals. Galvanized tank tees used in conjunction with galvanized nipple and fittings solves the problem. It is important to note that some plumbing codes do not allow the use of galvanized fittings and nipples, one must verify that galvanized tank tees meet all the applicable plumbing code requirements.

limited to installations on galvanized pressure tanks without a bladder. Galvanized tees are selected to eliminate the risk of galvanic corrosion between dissimilar metals. Galvanized tank tees used in conjunction with galvanized nipple and fittings solves the problem. It is important to note that some plumbing codes do not allow the use of galvanized fittings and nipples, one must verify that galvanized tank tees meet all the applicable plumbing code requirements.

PVC Tank Tees

PVC tank tees are a very competitive option compared to stainless steel, brass, and galvanized materials. They are extremely resistant to corrosion, they may not be as durable as metal tank tees, nor are there many configurations available. They may be a very suitable alternative, when proper PVC installation practices are followed, the use of a high-quality thread sealant paste rather than PTFE thread sealant tape and avoiding overtightening will reduce the risk of over stressing the female NPT accessory ports.

galvanized materials. They are extremely resistant to corrosion, they may not be as durable as metal tank tees, nor are there many configurations available. They may be a very suitable alternative, when proper PVC installation practices are followed, the use of a high-quality thread sealant paste rather than PTFE thread sealant tape and avoiding overtightening will reduce the risk of over stressing the female NPT accessory ports.

Tank Tee Installation Tip:

When connecting to a tank tee with dual MPT / FPT threaded line connections, it is highly recommended to use a FNPT fitting or valve to further support the MPT tank tee connection. See fitting on right hand side of the illustration. This adds extra support to the fixed wall thickness of the tank tee and has proven to virtually eliminate the risk of stress cracking failures due to overtightening.

Have further questions about this subject?

Head over to Boshart's Knowledge Base: technical product information, guidelines, and more.

SHARE