There are different ways to connect fittings to PEX pipe. One way is using copper crimp rings that clamp the pipe to the fitting. We have put together a guide of how to install ASTM-F1807 Metal PEX Fittings and ASTM-F2159 Poly PEX Fittings to PEX pipe.

In this blog we are going to go over what you need, pointers, how to install the crimp rings and how to ensure they are properly connected using a GO/NO-GO gauge. Please review all installation instructions before getting started.

Tools Required

- Pipe Cutter

- Crimp Tool

- ASTM-F1807 Crimp Ring GO / NO-GO Gauge

Getting Started

At the start of a PEX installation a “test” crimp should be done to ensure that the crimp tool is adjusted and working properly. Over time normal wear tends to increase the crimp diameter. If the joint fails the go/no-go gauge testing, adjustment or replacement is required. It is important to maintain and adjust the tool following the manufactures instructions.

The system can be “hand fit” together to finalize the layout, then you can go back and crimp each connection to make it permanent. After crimping all connections, the system can be pressure tested immediately. Crimp ring connections are ready for service whether the installation temperature is hot or cold, unlike Cold Expansion PEX (CEP) connections which require a wait time for the pipe to return to a set position.

Installation Instructions

Step #1

Step #1

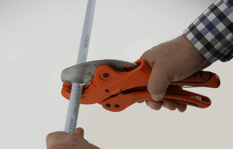

Using a pipe cutter, cut the pipe to the desired length making sure the cut is smooth and square to the end of the pipe. A rough, jagged, or angled cut may result in a failed connection. Do not use a hacksaw.

Step #2

Step #2

Select the correct size of copper crimp ring and slide the ring approximately 2” past the end the of the PEX pipe.

.png?width=177&name=insert%20fitting%20(1).png) Step #3

Step #3

Insert the fitting into the PEX pipe until the pipe is against the shoulder of the fitting.

Step #4

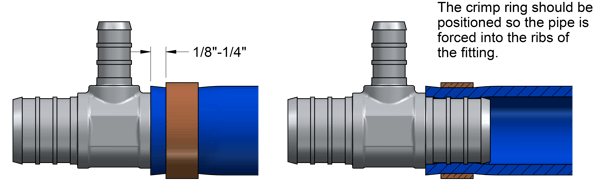

Slide the ring back towards the fitting, positioning the crimp ring 1/8” - 1/4” from the end of the pipe. This distance is critical to ensure that the crimp ring is positioned directly over the ribs or barbs of the fitting. See illustrations below.

Step #5

Step #5

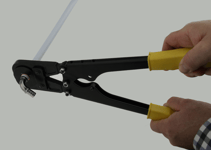

Center the crimping tool jaws over the ring. Holding the tool at 90 degrees to the fitting, close the jaws completely.

Step #6

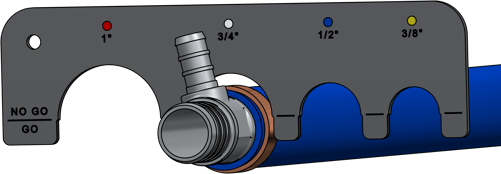

Check every crimp joint using a GO / NO-GO gauge. Hold the gauge at a 90-degree angle and slide it over the crimp ring. Instruction on using two types of gauges are detailed below.

Type A - Single Slot – GO / NO-GO Stepped Cut-Out

This type of gauge is faster to use as the gauge only needs to put onto the crimp ring one time.

When crimped properly the crimp ring will enter the U-shaped cut-out up to the line between the GO and NO-GO markings and stop midway. If the gauge can be rotated around the circumference of the crimp ring, the joint has been made correctly. However, If the crimp ring does not enter the first step the ring has not been crimped enough, or if the ring enters all the way to the bottom of the U cut-out the crimp ring is over compressed. If the joint fails either of these two tests, then disassemble the joint and return to Step 1.

GOOD CRIMP – Ring enter gauge part way stopping at the NO-GO step

GOOD CRIMP – Ring enter gauge part way stopping at the NO-GO step

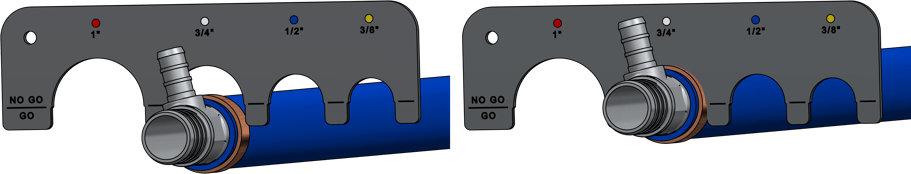

BAD CRIMP – (Left) Ring will not enter the GO step

(Right) Ring enters gauge all the way into the NO-GO step

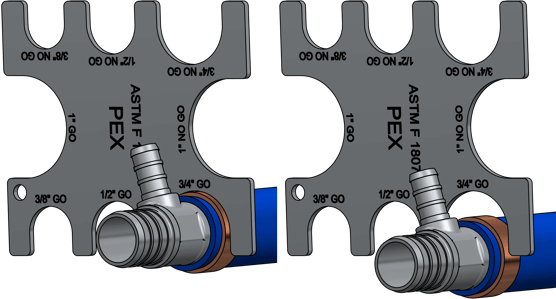

Type B Double Slot - GO and NO-GO Cut-Outs

This type of gauge is quite simple to use however it requires that a GO test be performed first and then the gauge must be re-positioned to perform a second NO-GO test.

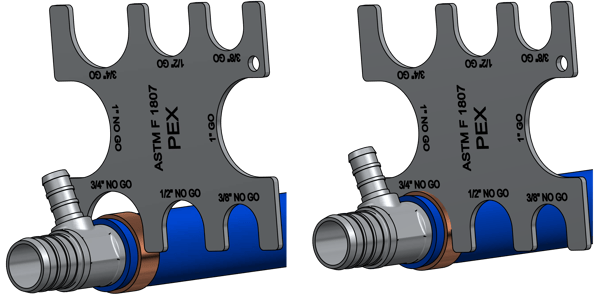

If the crimp ring fits into the “GO” slot and can rotate around the circumference of the crimp ring, the joint has been made correctly. Mark the fitting to indicate all the connections have been completed and tested. In the event the joint does not fit into the “GO” slot then the joint was not formed correctly. An improper crimp has been formed when (A) the “GO” slot does not fit over the ring or, (B) the “NO-GO” slot fits over the ring. If the joint fails either of these two tests, then disassemble the joint and return to Step 1.

(Left) GOOD CRIMP – Ring fits in GO gauge

(Right) BAD CRIMP - Ring does not fit in GO gauge

(Left) GOOD CRIMP – Ring does not fit into NO-GO gauge

(Left) GOOD CRIMP – Ring does not fit into NO-GO gauge

(Right) BAD CRIMP - Ring fits into NO-GO gauge

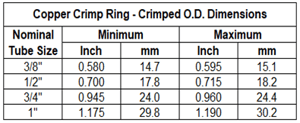

I f a GO / NO-GO Gauge is not available a micrometer or vernier can be used to measure outside diameter (O.D.) of a crimp ring after it has been crimped. A properly crimped ring will measure within the range detailed in the chart.

f a GO / NO-GO Gauge is not available a micrometer or vernier can be used to measure outside diameter (O.D.) of a crimp ring after it has been crimped. A properly crimped ring will measure within the range detailed in the chart.

Knowing what to do before starting the project can help make it easier and cut back on mistakes. Taking a little extra time to ensure each and every copper crimp ring is crimped properly may seem excessive but can prevent a leak down the road. Remember, these instructions apply to both metal and poly PEX fittings. Click here to see how to remove copper crimp rings ensuring the fitting isn't damaged and can be used again!

Have further questions about this subject?

Head over to Boshart's Knowledge Base: technical product information, guidelines, and more.

SHARE