Polytetrafluoroethylene. Sorry, what? You may have never heard that term, but I'm sure you've heard PTFE once or twice. PTFE stands for Polytetrafluoroethylene which is a synthetic polymer compound. Basically, it is a solid that is made from carbon and fluorine. PTFE is commonly used with PTFE tape.

PTFE thread seal tape is used to make watertight connections on metal NPT fitting pipe joints.

It is very important that you apply the tape correctly. We have broken this down into 5 easy steps. Let's take a look.

Warning: PTFE thread seal tape is not recommended to be used on NPT threaded connections when you are using Schedule 40 or 80 PVC. This is because when wrapping the PTFE tape, it will add bulk and will lubricate the joint which increases the risk of cracking the female PVC fitting.

Preparation

Before you start the process of wrapping the pipe threads, you need to make sure that the threads are not damaged in anyway and are clean and free of any debris.

To determine what kind of PTFE tape your system requires is also very important. To find out the different PTFE tapes available, check out our blog, Thread Sealant Tape: Where and How to Properly Use it.

5 PTFE Wrapping Steps

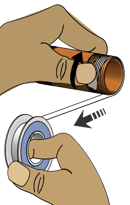

Step 1: First you will need to hold the fitting or nipple in your left hand and apply the PTFE thread seal tape to the male threads. Make sure to hold the tape tightly in place using your thumb while also pulling the tape tight to ensure the tape forms into the threads. You can then start to wrap in the direction of the threads (clockwise for right handed threads). You will wrap the pipe in the opposite direction that you will screw it into the fitting which will prevent the tape from unraveling during the assembly process.

thread seal tape to the male threads. Make sure to hold the tape tightly in place using your thumb while also pulling the tape tight to ensure the tape forms into the threads. You can then start to wrap in the direction of the threads (clockwise for right handed threads). You will wrap the pipe in the opposite direction that you will screw it into the fitting which will prevent the tape from unraveling during the assembly process.

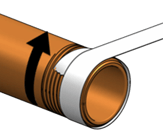

Step 2: Now you can start the first wrap. You need to ensure that the tape fully covers the end of the thread, partially wrapping the end of the fitting while not covering the opening. Be sure to wrap the entire thread as it will reduce any risk of it seizing or galling.

Step 2: Now you can start the first wrap. You need to ensure that the tape fully covers the end of the thread, partially wrapping the end of the fitting while not covering the opening. Be sure to wrap the entire thread as it will reduce any risk of it seizing or galling.

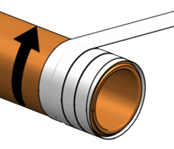

Step 3: Next, you need to maintain tension on the tape to make sure it is securely wrapping around the threads, forming into the thread profile. When you wrap the tape 3-5 revolutions, overlapping the tape, you will work gradually away from the end of the thread to completely cover the threads.

Step 4: Once you have finished wrapping the threads, hold the tape with thumb and forefinger. You can then pull it quickly, ripping the tape from the spool. Smooth out the loose end of the tape over the threads, making sure nothing is sticking up or bunched together.

Step 4: Once you have finished wrapping the threads, hold the tape with thumb and forefinger. You can then pull it quickly, ripping the tape from the spool. Smooth out the loose end of the tape over the threads, making sure nothing is sticking up or bunched together.

Tip: When you have finished wrapping, you can use the edge of the spool to form the tape around the threads, preventing any bunching or binding when

you tighten up the pipe.

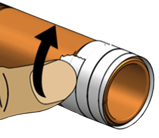

Step 5: Now that the threads are properly wrapped and there is no bunching or tape sticking out, you can thread the pipe into the fitting.

Thread Sealing Compound

Did you know that you can use thread seal tape in conjunction with thread sealing compound? It's true! When the male threads are properly wrapped with the PTFE tape, you can apply a coating of the thread sealing compound over the PTFE tape before you thread the pipe into the fitting. Applying the thread sealing compound on top of the tape will fill any remaining gaps that the PTFE tape didn't get between the male and female threads. Any excess thread seal compound will be forced out of the fitting when assembled.

Did you know that you can use thread seal tape in conjunction with thread sealing compound? It's true! When the male threads are properly wrapped with the PTFE tape, you can apply a coating of the thread sealing compound over the PTFE tape before you thread the pipe into the fitting. Applying the thread sealing compound on top of the tape will fill any remaining gaps that the PTFE tape didn't get between the male and female threads. Any excess thread seal compound will be forced out of the fitting when assembled.

In Conclusion:

When wrapping PTFE tape, be sure to take your time. It is much easier to do it correctly the first time, no matter how long it takes you instead of wrapping it incorrectly and running into issues. Be sure to also keep in mind to apply thread sealing compound to add an extra layer of security on the threading.

Have further questions about this subject?

Head over to Boshart's Knowledge Base: technical product information, guidelines, and more.

SHARE