With so many different ball valves on the market it can be hard to know what the differences are. Two important properties to understand about ball valves are the port size and the construction of the valve. In this blog we will explore both of these properties and the different types available.

All About Port Sizes

Port size is the size of the opening that fluid can travel through when the ball valve is in the open position. There are different types of port sizes when it comes to ball valves: standard, reduced, and full port.

Full Port

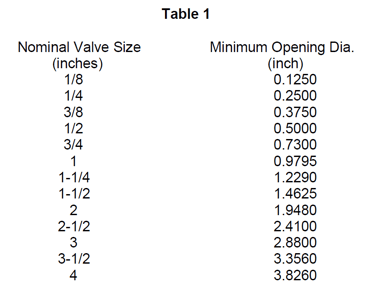

In a full port ball valve, there is no restriction to the flow through the valve because the opening in the ball is close to the same size as the pipe. The opening must meet the minimum diameter laid out in IAPMO IGC 157-2009. An over size ball is necessary to meet this requirement, making the ball valve larger. Table 1 shows the minimum Opening Diameter (or port size) that is required for a ball valve to be considered full port.

Standard Port

For a Standard port ball valve, the opening through the ball is smaller than the size of the pipe. This creates flow loss, but standard port ball valves are smaller than full port valves because the ball is not as big.

Reduced Port

Reduced port ball valves have an opening through the ball that is one pipe size smaller than the valves pipe size. Reduced port ball valves can also be considered standard port ball valves.

All About Ball Valve Construction Methods

Depending on the desired port size of a ball valve there are different ways they can be constructed. The construction of the ball valve generally refers to the number of pieces that are put together to make the ball valve.

One-Piece

In a one-piece ball valve the connection ends are manufactured as a single solid piece and the ball is added from the top or the bottom of the valve. The benefit of this is there are no seams where leaks or fails can occur. A downside is that all one-piece ball valves are standard port because of restrictions to the size of the ball being inserted.

Two-Piece

A two-piece ball valve is constructed from two separate valve body pieces allowing for easier installation of the ball and seats. Having the valve split allows for a larger ball to be installed creating a full port ball valve. A two-piece ball valve has a seam where the two pieces are connected, causing a weaker part of the valve if it is installed incorrectly. These are generally the most common as they do not restrict the flow through the valve.

Three-Piece

A three-piece ball valve is bolted together once the ball and seats have been added. The advantage to these ball valves is that they are repairable and heavy duty. The disadvantage, on the other hand, is that they are very expensive, which means it doesn’t always make the most economical sense to use a three-piece ball valve.

Molded-in-Place

The term molded-in-place refers to the construction of PVC ball valves. This is where the ball and stem are placed in the mold and the resin is heated and injected around the assembly. By constructing ball valves this way there are no seams, as you would see in a two-piece construction, making these a strong one piece design.

Some of these differences are harder to see than others, but now you can better understand the importance of knowing the desired port size and construction method for ball valves. Knowing more about port sizes and construction methods helps when deciding which ball valve is right for your application. With these different combinations there are lots of ball valves to choose from!

Have further questions about this subject?

Head over to Boshart's Knowledge Base: technical product information, guidelines, and more.

SHARE