In this Webinar, we take a look at what a pressure switch is and explore the different types of pressure switches that Boshart offers. We even provide some helpful tips to make ordering a pressure switch a breeze! Check out the video below.

For Square D technical sheets and for any Square D pressure switch catalogs, check out the Square D website.

If you would like more information on Hubbell pressure switches and want to take a look at any resources, check out their website here.

Transcript

Hello everyone. Welcome to our webinar on pressure switches and thank you for joining us today.

My name is Braedlyn McEwen and I am the Social Media and Content Coordinator here at Boshart Industries. As you can see, my bitmoji looks a little different. I am expecting in November and will be going on maternity leave. While I am away, Melissa Bender will be taking over the webinars. Today, we will be presenting together.

We are joined today by our technical team: Will Bender, our Quality Assurance Analyst, Steve Hudson, our Quality Assurance Manager and Paul Erb, our Research and Development Manager. They will help answer your questions at the end of the presentation.

During the presentation, feel free to type out any questions that you have. We will do our best to answer all questions after the presentation. If there are any questions that we can’t get to, we will reach out following the presentation.

If you want to type out a question, look for the side bar on the right-hand side of your screen. Then, click on the button that looks like an arrow in a box . This will open a menu with a question box. You can type out your questions there and we will be able to see them. Please note the slide number if you’re referencing a specific slide. The slide numbers will be displayed on the bottom left corner of the slide.

Overview

To start, we will look at what a pressure switch is and connection types. We will then move on to the different types of pressure switches and discuss the features of a Boshart standard pressure switch. We will end the presentation with helpful tips and questions.

Let’s get started with what a pressure switch is.

What is a Pressure Switch?

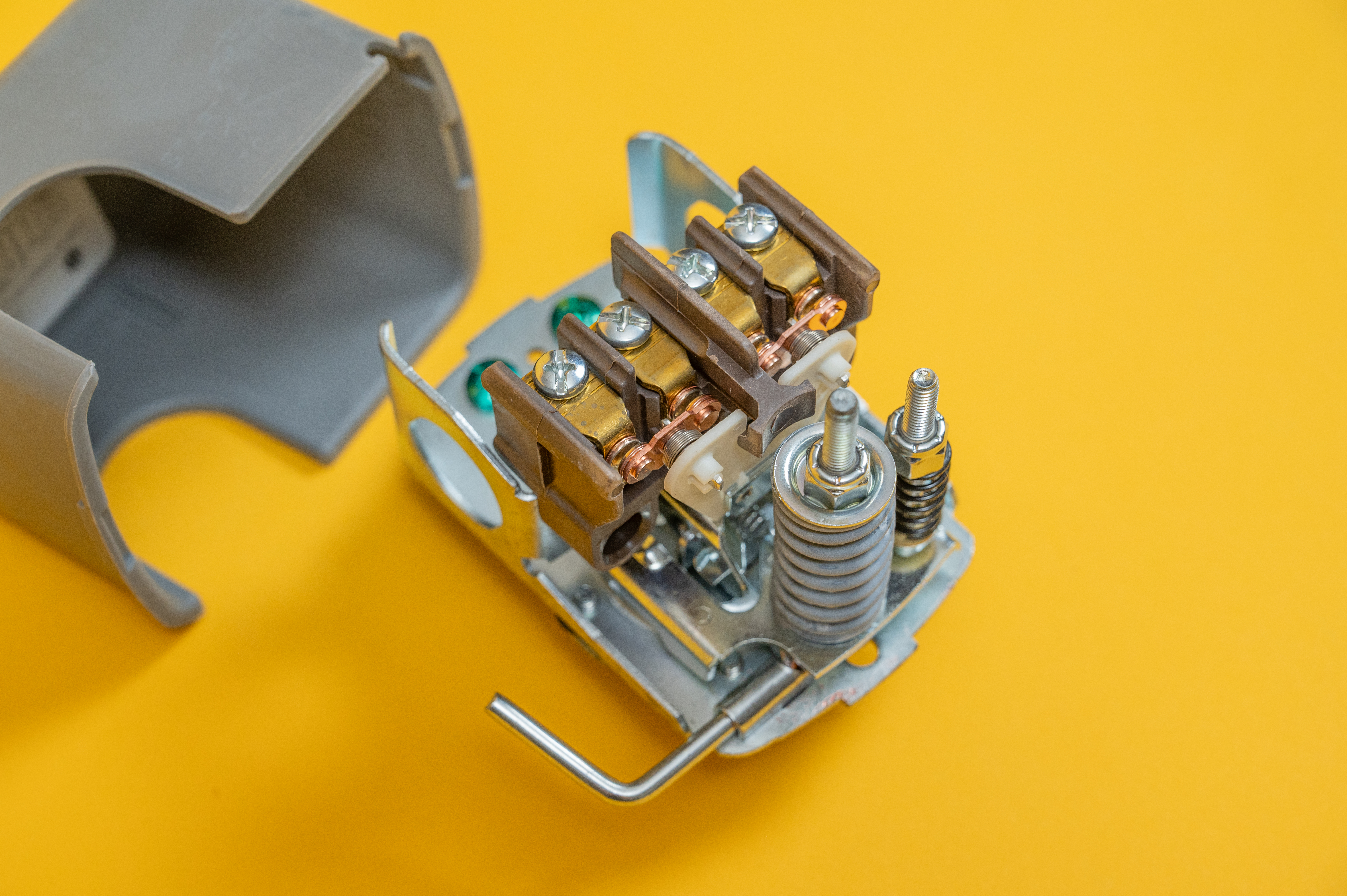

A pressure switch is most often used to turn a water pump on and off by sensing a change in system pressure. A pressure switch will sense when a predetermined pressure point is reached and will open or close an electrical switching element.

In addition, switches can be used to control air compressor pumps. They are commonly used to make or break electrical circuits at selected pressures or other devices such as alarms used in many industrial applications.

Pressure switches are rated under NEMA, the National Electrical Manufacturers Association, ranging from 1-13 for different uses.

All pressure switches have two operating points known as the cut-in and cut-out. The cut-in point, also known as the reset point, is a result of falling pressure and starts the pump. The cut-out point, also known as the trip point, is a result of rising pressure and stops the pump.

Turn the nut on the large spring clockwise to raise both the cut-in and cut-out pressure. Turn the nut counterclockwise to lower both the cut-in and cut-out pressure settings.

For accuracy and to optimize the life of the switch, the cut-in and cut-out set points should be in the middle of the operating pressure range.

Following the presentation, this technical sheet outlining the minimum and maximum cut-in and cut-out ranges will be available for download for your reference.

Differential, also known as the dead-band, is the difference or spread between the cut-in and cut-out points. On most switches, the differential between the cut-in and cut-out can be adjusted, however, some switches have fixed, non-adjustable differentials. Some applications require a wider or narrower spread between the pump-on and pump-off set-points. To adjust, turn the nut on the small spring clockwise to raise only the cut-out pressure. Turning it counterclockwise will lower the cut-out pressure only.

Connection Types

¼” FPT connections are the most common and are ideal for installing on tank tees. They typically use 3” nipples to lift the switch up high enough to allow the replacement of the pressure gauge without removing the switch. They can also be easily adapted to connect to tubing using barbed tube, compression or quick connects for any pressure connection desired.

Additionally, there are other less common connections available for attaching directly onto jet pumps or to poly tubing. If you’re interested in more information about connection types, please reach out to your Inside Sales Rep.

Now, we will look at a selection of the different types of pressure switches available in our catalog.

Different Types of Pressure Switches Available

Boshart carries multiple brands of pressure switches. There are several reasons why we offer these different brands:

- There are often applications where one brand of switch will cover the desired cut-in and cut-out settings, whereas another brand cannot

- The differential ranges can vary from brand to brand and in some applications, a Hubbell switch may meet the desired need whereas a Square D switch will not and vice versa

- There will sometimes be differences in the electrical rating of a switch which makes one brand more suitable than another

- In some cases, it simply comes down to customer brand preferences

It's important to know that if one pressure switch cannot be adjusted to meet your application's settings, there may be another brand that can meet your needs.

Most pressure switches are standard pressure switches. Typically, standard pressure switches are best used with pumps up to 1.5 horsepower on 120 volt motors and up to 2 horsepower on 240 volt motors.

Unless otherwise specified, all pressure switches are supplied with NEMA 1, General Purpose Enclosures. These enclosures are for indoor use only. They protect the switch from debris and protect people from the components within the switch.

Low pressure cut-off switches include all the features of standard pressure switches. The only difference is that low pressure switches have an off, start and auto feature which helps preserve the life of the pump.

If pressure in the system were to drop approximately 10 PSI below the set cut-in point, the switch will open and turn off the pump. When the condition has been relieved, the manual lever can be turned back to the start position and, if pressure is restored while holding there, the switch resumes normal operation.

Hubbell’s GARD-IT pressure switch is wired in series with a conventional Furnas pressure switch. It is designed to protect your water pump or air compressor motor by automatically shutting your pump off if water or air pressure gets too low. Once pressure returns to normal, you simply press the manual reset button to restart your system.

Hubbell’s HI-GARD switch is also wired in series with any system pressure switch. This special pressure switch is designed to cut-out when a preset pressure is reached. It must be manually reset. These pressure switches are used when it is desirable to limit the maximum pressure in a system.

Reverse action switches will cut-in on rising air or water pressure. They are designed to ground ignition on gas driven pumps and compressors when a desired maximum pressure is reached. They can also act as a low-pressure alarm or to prevent pump operation at low pressure. The reset lever is optional.

Manual on/off switches offer an auto/off lever. The lever allows you to manually turn off your pump system for extended periods of time. When the lever is in the "on" position, the switch is in automatic operation, and will turn on and off at the preset cut-in and cut-out pressure settings.

Square D offers a standard duty air switch designed for small electric air compressors up to 2 horsepower on 120 volt motors and up to 3 horsepower on 240 volt motors.

They differ from most pressure switches as they have models with fixed differential of approximately 20, 30 or 40 PSI. The multiple factory "off" setting can be ordered. The "off" setting can also be adjusted up to a maximum of 200 PSI depending on which model is selected. They can be ordered with an auto/off lever as well.

The pulsation plug slows the flow of fluid to the diaphragm of the pressure switch to reduce the surge rate.

The most common application for the switch with the pulsation plug is for piston pumps. Without the plug, the spike in pressure would cause the contacts to open, shutting off the power to the pump only to be turned right back on. The pulsation plug can be easily installed into any brand of switch with a ¼” FPT pressure connection.

Medium duty pressure switches are best used with larger pumps up to 2 horsepower on 120 volt motors and up to 3 horsepower on 240 volt motors.

Hubbell’s 69J series is the most adaptable switch on the market. It offers the user the flexibility to build the pressure switch around the compressor, and not the other way around. The unloader can be mounted on either side, and can be rotated to any of eight different positions, allowing for quicker assembly and shorter tubing.

These Hubbell medium duty air pressure switches have the option to include an auto/off lever, an unloader valve or both. The unloader valves are designed to unload the pump and air line pressure after motor shutdown.

Heavy duty air or water pressure switches are used with large pumps and commercial compressors up to 250 PSI, 2 horsepower on 120 volt motors and up to 5 horsepower on 240 volt motors. They can operate as high as 5 horsepower with 575 volt motors.

Heavy duty air pressure switches can also be equipped with unloader valves as previously mentioned.

Square D’s 9013GSR series is rated to both NEMA 7 and 9. NEMA 7 enclosures are designed to contain an internal explosion without causing an external hazard. NEMA 9 enclosures are designed to prevent the ignition of combustible dust. These enclosures are intended for indoor use in hazardous locations.

Type 3R switches are intended for outdoor use. They provide a degree of protection against rain and ice formation. Please be aware that these are not water-tight. Moisture can enter when subjected to a stream of water under certain conditions. NEMA 3 and NEMA 3R enclosures are typically used for housing power distribution and other electrical components that need to be protected in an outdoor environment. Outdoor weatherproof enclosures cannot be used with auto-off disconnect switches.

When choosing a pressure switch, ensure not to exceed the manufacturer’s maximum pressure temperature and electrical ratings. Electrical equipment should be serviced only by qualified electrical maintenance personnel. No responsibility is assumed by Boshart Industries or the manufacturer for any consequences arising out of the use of this material.

Now, we will look at the benefits of Boshart standard pressure switches, and the features that set them apart and make them the best choice for the professional installer.

Standard Pressure Switches

Most back plate connections on standard import switches are spin friction welded into the flange. This type of weld is weak, and has been known to fail, resulting in significant property damage.

The back plates on Boshart standard duty pressure switches are custom made using a process which welds the hex connection to the metal flange, resulting in a connection that is 250% stronger than the friction spin weld connection method.

Boshart has terminal block dividers which retain the wire under the screw head on the right-hand side of each terminal screw. The divider helps stranded wires remain secure under the screw head when the screw is tightened and ensures a good electrical connection.

Contractors like this feature because it saves time. Solid conductors can be stripped and inserted under the right-hand side without having to bend the wire into a “U” shape to wrap around the terminal screw. Simply insert and tighten without having the wire pop out.

Many pressure switches on the market have very little, or in some cases, no clearance for conduit lock nuts, sometimes referred to as jam nuts. This makes it very difficult to tighten due to interference with the terminal block.

Boshart’s custom terminal block design provides clearance around the conduit openings, making it easier to install.

Another common issue with import switches is that the threads strip in the brass terminal screw lugs which are drilled. This leaves a thin cross section and little thread engagement for the terminal screws.

With Boshart standard switches, the terminal screw lugs are form punched with a die that displaces the metal and doubles the threadbare cross section. This increases the number of engaged threads from two to four.

Since this change was made many years ago, there has not been a single report of a stripped thread.

Another common issue with import switches is that the threads strip in the brass terminal screw lugs which are drilled. This leaves a thin cross section and little thread engagement for the terminal screws.

With Boshart standard switches, the terminal screw lugs are form punched with a die that displaces the metal and doubles the threadbare cross section. This increases the number of engaged threads from two to four.

Since this change was made many years ago, there has not been a single report of a stripped thread.

Terminal Screws

Typical import switches have short terminal screws. When installing 10 AWG and heavier wire, the terminal screws need to be turned out further to fit the wire under the screw head. Often, this results in the screw being turned right out of the terminal lug.

Boshart terminal screws were lengthened by 30% to eliminate this issue.

Standard import switches use Hexavalent Chromium, also known as Chromium 6. Manufacturing this plating is banned in North America and Mexico. The process is not only harmful to the environment; it’s also incredibly harmful to the health of factory workers. Despite the harmful environmental and health effects, most importers opt to buy the product anyways because it’s inexpensive.

Instead of using this harmful product, Boshart uses Trivalent Chromium, also known as Chromium 3. We pay a premium to use this more expensive, eco-friendly plating because we believe that it’s the right and responsible thing to do. Plus, salt spray testing has proven that this eco-friendly plating is more corrosion resistant.

Many import switches are not certified to ensure compliance with the reduced lead content requirements. They are also often missing lead-free markings on the cover.

Boshart’s switches are No-Lead certified to NSF-372 Standard. The covers have a large No-Lead certification mark making identification of compliance to the Safe Drinking Water Act easy for inspectors. The No-lead certification listing number is written inside the cover, along with CSA and UL electrical listings.

In addition to the No-Lead mark, our switch covers are clearly marked to identify standard and special application switches. This makes it easy to identify low-pressure cut-out switches from auto – off switches, which otherwise are identical in appearance.

Boshart covers are designed with a larger name plate insert allowing for more flexibility in private labeling. Contact a Boshart sales representative for details on minimum order quantities.

Now, we will look at some helpful tips.

Helpful Tips

Here are three things to know before ordering a switch.

First, you need to know your desired system pressure. This covers the cut-in, the cut-out and the differential. Second, you need to know your power needs. Look at the pump for what sort of power is going to go through the switch. Third, you need to know if you need a special application switch like a low pressure cut-off switch, for example.

We have a great resource that you can find on our BoshartU blog about how to properly adjust your pressure switch. The blog includes adjustment tips and a step by step process on how to accurately adjust the cut-in. Check it out at blog.Boshart.com.

Overview

That is the end of the presentation today. Visit our BoshartU blog to learn more about our products and be sure to subscribe to receive new content updates.

Stay connected with us by following Boshart Industries on Instagram, LinkedIn, and Facebook.

Thank you again for joining us today. Check out our website to learn more about our products and subscribe to our blog to receive new content updates. Enjoy the rest of your day.

Have further questions about this subject?

Head over to Boshart's Knowledge Base: technical product information, guidelines, and more.

.png)

SHARE