The conversation and battle between brass and plastic PEX fittings has been going on for many years. Like most things, there are pros and cons to each material. With the introduction of Stainless Steel PEX fittings, the conversation changes as Stainless solves many issues with traditional Brass and Plastic PEX crimp fittings.

In this blog, we are going to explore what the conventional opinions are between brass and plastic and how Stainless PEX fittings stack up.

Brass vs Plastic PEX Fittings – The History

Like I mentioned before, the debate between brass versus plastic has been going on for years. There are plumbing contractors who swear by one or the other, and then there would be another group of people who would use each material based on application.

When talking about Brass, there are many people who continue to use it as their main material because of the confidence they have from a strength perspective. Some contractors feel that plastic fittings are weaker and are nervous to use them.

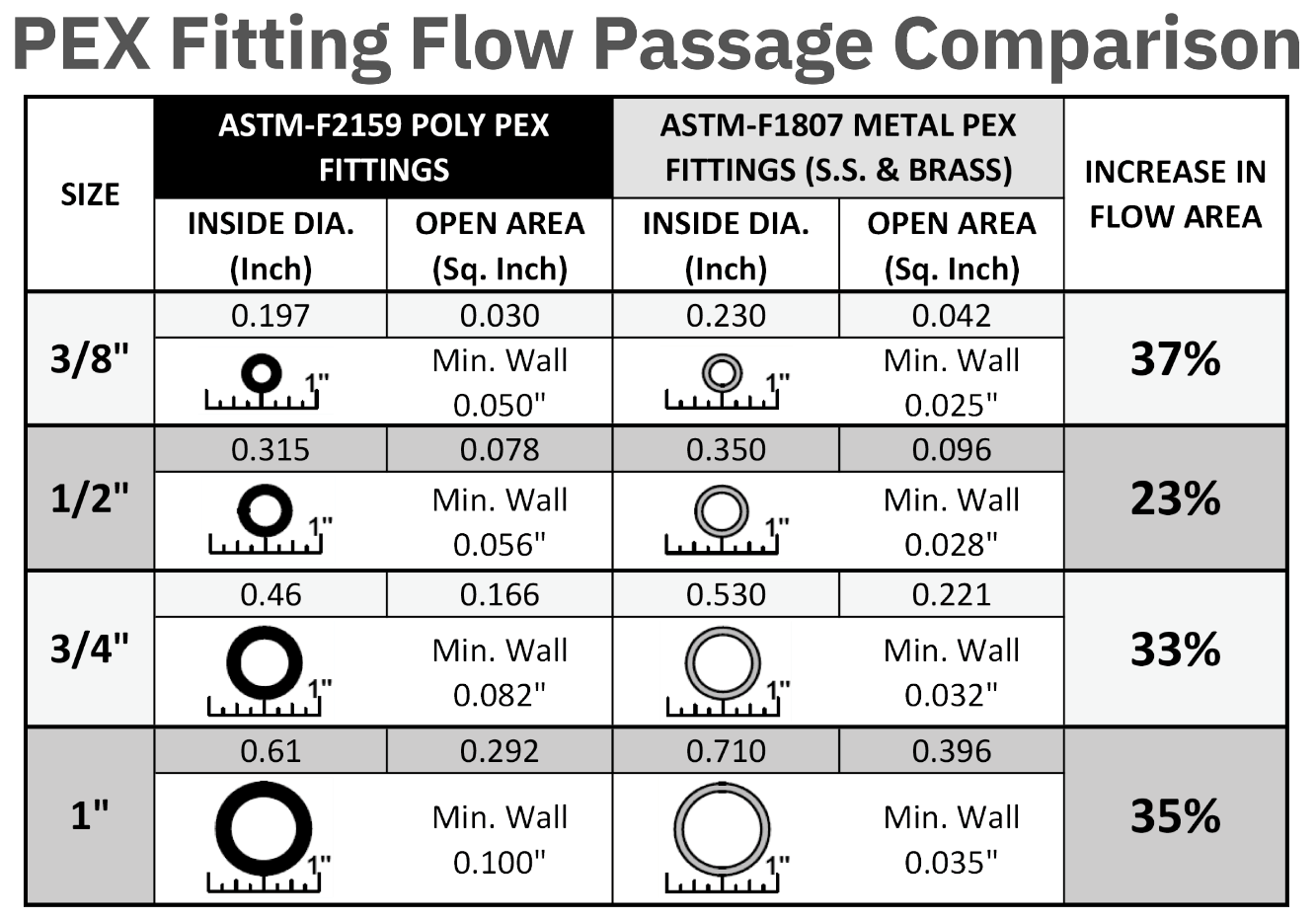

Another concern that contractors have with using plastic PEX crimp fittings is the thicker wall requirement under ASTM2159 Standard, resulting in a reduced ID which restricts flow. Metal (Brass and stainless) crimp fittings manufactured to ASTM F1807 having larger flow passages. If you are using plastic crimp fittings throughout a whole house, this can cause significant flow restriction.

In saying this, there are some applications where plastic would be much better than brass. For example, when you have poor water quality, plastic is a superior choice, as brass can corrode and leak in these situations. This problem has been complicated with the introduction of No-Lead Brass, as not all low lead brasses are created equal. Due to the high zinc levels combined with very thin wall structure of brass PEX crimp fittings, any amount of corrosion can be problematic. Dezincification associated with high zinc alloys increases the risk of fitting failure.

Stainless vs. Brass vs. Plastic PEX

So, as you can see there is uncertainty in the use of plastic and brass materials. In saying that, Stainless PEX crimp fittings incorporate all the positive features of both plastic and brass, providing high strength and larger flow passages.

Austenitic stainless steels, in particular 300 series, are inert against nearly all heat transfer fluids due to the chromium (III) oxide passivation layer covering the surface. When deionized water is used in glycol antifreeze solutions in hydronic systems, stainless steel is considered to be appropriate for wetted surfaces.

There are a few key aspects of Stainless PEX that make it a great choice for contractors. The main advantages are corrosion resistance, flow rate and overall strength.

Corrosion Resistance

As I mentioned above, one of the issues with Brass (especially over the past few years) is corrosion resistance. Stainless steel is being adopted more and more in many plumbing applications due to the affects that poor water quality has on brass. This has become even more of a problem with PEX systems.

In the past, most plumbing systems were made with copper pipe and fittings. Copper is susceptible to corrosion, but there are a few differences that you need to keep in mind. The first one is that copper and brass are not the same. Copper is much more corrosion resistant than brass because brass is an alloy made up of multiple materials (mainly Copper and Zinc). PEX fittings made from 304 stainless steel do not contain zinc, and therefore are not affected by dezincification.

Now that many plumbing systems are moving to plastic PEX piping, the corrosion only has one place to go – the brass fittings which make up a small percentage of the surface area of the plumbing system. With systems totally made up of copper pipe and copper / brass fittings, the corrosion is evenly spread on a much larger surface area throughout the system. This is the reason the conversation around corrosion resistance is so important when talking about PEX fittings. Stainless steel’s superior corrosion resistance will outperform brass, especially due to the very thin wall structure of metal PEX crimp fittings.

Flow Rate

Flow rate is also a very important aspect to think about. The main reason is because the fitting inserts inside the pipe, rather than sealing on the outside like other systems. This inherently reduces the flow rate. As I mentioned above plastic PEX has a smaller ID than brass and stainless which will further reduce flow.

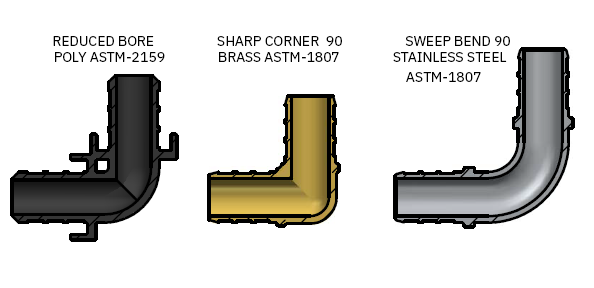

This may not seem important, but when there are numerous fittings in a system, this flow restriction can cause a lack of pressure down the line when multiple fixtures are in use. While Brass and Stainless PEX fittings have the same standard and ID, the shape of the fitting also comes into account.

The main contributor to reduced flow is a 90-degree elbow. When the water hits these fittings, this creates a lot of turbulence, which causes friction loss and reduces flow. Boshart’s Stainless Steel PEX Elbow was designed with a sweep to significantly reduce these effects.

Overall Strength

Strength of a PEX fitting is important to think about as well. The main reason for this is because of water hammer. This is when a shockwave is sent through a plumbing system when a valve is suddenly closed and water “hammers” back down a pipe which causes stress on the pipe and fittings. This is a huge reason why supporting the pipe and fittings properly is so important.

As you can see in the image below, Stainless is much stronger than Brass and Poly.

History has proven that both brass and plastic PEX fittings have their advantages and disadvantages.

Stainless PEX fittings eliminate the need and cost for dual inventories, as they feature the best attributes of both brass and poly. The superior corrosion resistance, flow rates, and strength of these fittings demonstrate their versatility and how they can be used in a wider range of applications.

Stainless steel PEX fittings are an excellent choice for your next system.

Have further questions about this subject?

Head over to Boshart's Knowledge Base: technical product information, guidelines, and more.

SHARE