PEX pipe has been around for decades in the plumbing industry, so it's easy to think that innovation might be stagnant. While poly and brass fittings have long been the standard for PEX plumbing systems, in 2020 we announced our Stainless Steel PEX Fittings which challenged the conventional.

Now, we've done it again.

We are proud to announce the newest edition to our PEX line: Cold Expansion Stainless Steel PEX Fittings.

In this blog, we'll dive into cold expansion stainless steel PEX fittings, their benefits over other materials, and why they are the right fitting for your job.

Most of you are already familiar with our Stainless Steel Crimp PEX fittings. Much like those, our new cold expansion PEX fittings carry the same material benefits. However, there are some more benefits to our stainless steel cold expansion PEX than you might assume. So let's dive in!

.png?width=710&height=888&name=MicrosoftTeams-image%20(9).png)

Understanding cold expansion stainless steel pex fittings

At first glance, the term "cold expansion stainless steel PEX fittings" is a bit of a mouthful, but the concept is quite simple.

Unlike crimp PEX connections, cold expansion PEX tubing expands around the fitting before returning to its original form, creating a secure and tight seal. PEX A has "memory", meaning that even after being stretched, it tries to return to its original form (hence creating a tight seal). PEX B/C does not have this memory property.

Crimp fittings simply insert into the unaltered tube and are clamped down (or crimped) with a metal ring outside of the PEX tube that sits overtop of the fitting. Because of this, the inner diameter of the passage is reduced where the fitting sits. This is one of the greatest advantages of cold expansion PEX systems over crimp.

These stainless steel fittings are meticulously designed and manufactured to adhere to the ASTM F1960 standard (which covers both plastic and metal fittings), ensuring their quality and reliability.

Benefits of stainless steel over brass & poly

Corrosion Resistance

One of the primary drawbacks of poly and brass fittings is their susceptibility to corrosion, either due to water conditions or inadvertent exposure to chemicals. Stainless steel shines in this aspect, being highly resistant to both scenarios. PEX fittings made from 304 stainless steel do not contain zinc, and therefore are not affected by dezincification. This durability ensures a longer lifespan and fewer maintenance hassles.

Additionally, now that many plumbing systems are moving to plastic PEX piping, the corrosion only has one place to go – the brass fittings - which make up a small percentage of the surface area of the plumbing system. With systems totally made up of copper pipe and copper / brass fittings, the corrosion is evenly spread on a much larger surface area throughout the system, which means it's far less of an issue in most scenarios.

If you're unsure about the longterm status of the water, it is better to err on the side of caution and use stainless steel PEX fittings for the peace of mind.

Superior Strength

Another thing to consider is the strength of the PEX fittings. This added strength makes them much more durable against water hammer. Water hammer happens when a shockwave is sent through a plumbing system. A valve suddenly closes and water “hammers” back down a pipe which causes stress on the pipe and fittings. This is a huge reason why supporting the pipe and fittings properly is so important.

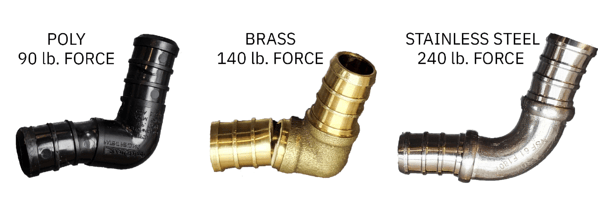

As you can see in the image below, Stainless is much stronger than Brass and Poly.

Even if water hammer isn't your biggest fear, there is no denying that a stainless steel fitting is that much stronger and long-lasting than poly or brass. If you want to know you've got the best possible fitting on the job, the choice is obvious.

Higher Flow Rate

Our Stainless Steel Cold Expansion PEX fittings are unique in the industry not only because they are the first of their kind, but unlike other PEX fittings, Boshart elbows have a sweep design. Our Stainless Steel Cold Expansion elbows have an 18.5% higher flow rate (at 40 PSI) than Poly Cold Expansion Fittings. This is an important factor to consider when choosing the most efficient fittings for your system.

A big contributor to a reduced flow rate in PEX systems is a 90-degree elbow. When the water hits these fittings, it creates a lot of turbulence, which causes friction loss and reduces overall flow. However, Boshart's Stainless Steel PEX sweep elbow significantly reduces these effects.

If you're thinking, "Well, I've never had a problem with flow before," it's important to remember that these things have a way of hiding for a time. Many homeowners will feel the impacts of this decision long after the job is completed and the contractor has left. Our sweep elbows give both contractor and homeowner alike the knowledge that friction isn't going to be as much of a problem in this water system.

Cold expansion vs. crimp: A matter of preference

The debate between cold expansion and crimp systems is similar to choosing between two high-performing tools.

Contractors often opt for a particular system based on familiarity, tools at hand, and workflow consistency. Is one objectively better than the other? It can be argued either way. Rather than get too caught up in this discussion, we prefer to recognize that a lot of it comes down to preference.

Now, even your preference can't stop you from choosing Stainless Steel PEX fittings because we've made them available in both cold expansion and crimp.

Boshart now offers both styles of PEX fittings in the stainless steel material ensuring that no matter the preference, your system will be the most durable it can be.

Whatever you decide, Boshart has a PEX fittings for it!

revolutionizing the plumbing and WATER-WELL industry

Boshart Industries was the first to the market with our Stainless Steel Crimp PEX Fittings. We are now, once again, the first to market with Stainless Steel Cold Expansion PEX fittings.

Choosing stainless steel means you have the ability to be cutting edge of a gigantic shift that’s about to take place in the market. Before it becomes the industry standard, you have the chance to use the latest and greatest in the plumbing world.

Historically, the plumbing industry is slow to change. This is a chance for you to flip the script and get ahead of the game.

Conclusion

In the ever-evolving realm of plumbing fittings, the introduction of cold expansion stainless steel PEX fittings marks a significant advancement. These fittings bring corrosion resistance, improved flow, and superior strength to plumbing systems, promising longevity and efficiency. Boshart Industries ensures that your choice is a flexible one by offering both cold expansion and crimp styles to cater to diverse needs.

As plumbing technology continues to evolve, embracing innovations like cold expansion stainless steel PEX fittings can bring your plumbing systems to a new level of excellence.

Have further questions about this subject?

Head over to Boshart's Knowledge Base: technical product information, guidelines, and more.

SHARE