When it comes to choosing a gear clamp, contractors have a ton of different options available to them depending on what they’re trying to accomplish. While there are many different ways to connect a hose to a pipe, gear clamps are ideal in many situations because of their versatility and reusability especially when making a connection that you might want to adjust later, gear clamps are particularly useful.

First, its important to understand what we mean by the term gear clamp. While most contractors will think of a worm gear or hose clamp, there are many different styles of gear clamp that you can choose from.

The Variety of Gear Clamps

Below are some of the gear clamps that are available on the market:

- Worm Gear Hose Clamps – This is by far the most common and popular gear clamp that can be used in a multitude of applications. If you don’t know what you’re going to need when you are on the job site, this is the type of gear clamp you want to have in your truck

- Plastic Hose Clamp – This is another general-purpose gear clamp that can be used instead of metal

- Constant Tension – This clamp is designed to provide a constant and even pressure around a hose connection

- Heavy Duty Hose Clamp - Very similar to the worm gear hose clamp but has a wider band and increased strength due to in-line housing

- Ear (Pinch) Clamp – These pinch clamps are optimal for applications involving soft or hard rubbers and plastic, this clamp cannot be re-used

- Snap-Fit Hose Clamp – Cost effective version of Ear (pinch) Clamps

- Screw Hose Clamps – A smooth clamp with no teeth, screw hose clamps are ideal for soft hoses and small diameters.

As you can see there are a ton of different types of gear clamps for many different applications, depending on your budget and application.

Most Common Gear Clamps

By far the most popular gear clamp (in our experience) is the worm gear hose clamp. You might hear this type of gear clamp referred to as a worm clamp or a hose clamp but for the sake of ease we will simply call it a gear clamp because all of these terms mean the same thing.

Because a worm gear hose clamp is by far the most common, it will be the focus of this discussion.

Choosing a Clamp: Application

First and foremost, when choosing a clamp, the contractor needs to consider where is it going to be used. Is it being used near potable water? Is it buried under ground? Is cost the most important deciding factor? These are just a few of the questions that need to be answered when choosing a clamp.

Boshart Industries carries three different series of clamps that we are going to briefly describe below. However, no matter what brand of gear clamp that you’re buying, chances are the clamps will come in similar materials but they might be called a different name. The important part is the type and grade of metal.

87 Series

87 Series

Boshart’s 87 series gear clamp is made up of 300 grade stainless steel (housing, band, and screw) and is considered to be the “do it all” gear clamp. This clamp is safe for potable water and can be buried underground without issues.

67 Series

Boshart’s 67 series gear clamps are made up of 200 grade stainless steel and are very similar to the 87 series in application, however they cannot be buried underground.

77 Series

77 Series

Finally, Boshart’s 77 series of gear clamps is our most economical offering, made up of 200 grade stainless steel but with a screw that is zinc plated. This means that it is not suitable for any application where corrosion is a concern, thus not being suitable for buried applications.

For more information on the specifics of Boshart’s different gear clamps, check out our blog here for more info: The Hidden Strength of a Better Gear Clamp

If you’re in doubt about what gear clamp to use, you cant go wrong on the 87 series of gear clamps because they can be used virtually without limitations. Because gear clamps are a fairly inexpensive product anyways, this is cheap insurance that you wont choose the wrong clamp and risk catastrophic failure.

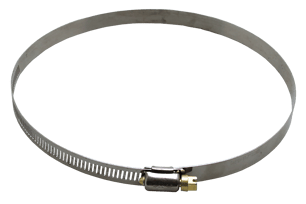

Choosing a Clamp: Size of Clamp

After you know where your gear clamp will be used, the next step is figuring out the size of clamp that you need.

A note about terminology: When someone says the term “2 inch gear clamp” they’re referring to the maximum diameter of the pipe this clamp can cover they are not referring to the circumference of the band.

Most contractors might think that using an oversized clamp is not particularly risky. However, there is good reason to being thoughtful about choosing the right size of gear clamp.

There are three main reasons you do not want to use a gear clamp that is too big:

- You are wasting money on paying for more clamp than you are actually using.

- The long tail of the band creates more opportunity to have something snag on it and pull the band loose.

- By far the most important, particularly in circumstances with small pipes, the gear clamp when tightened too far will create a D shape around the circumference of the band which means the clamping is uneven on the pipe. This can lead to damaging the pipe or a lack of tight seal.

As for the width: most gear clamps bands are between 5/16” up to ¾”. However, the most common band width is ½”. In our experience, there is not a significant difference between bands to the degree that a contractor should be concerned that the band on their gear clamp might not be wide enough for a particular application.

Choosing a Clamp: Your Industry

If you are a contractor that works in sump and sewage for example, then many of the pipes you are working with are likely 3” in diameter (or more) and therefore you will want more clamps on hand that are within these ranges.

If you are a plumber, most of your pipes are probably ½” up to 2” so you can save money by only buying gear clamps in and around this size. Anything larger than 3” is going to be a waste of money for you and runs the risk of uneven surface pressure of the band.

If you are a generalist plumber who works on all kind of different jobs, you’re going to want a whole range of sizes to accommodate whatever job you are called to so that you’re always prepared.

Summary

As you can see, there is more to consider about choosing the proper gear clamp than most contractors and plumbers realize. By taking the time to consider everything in this article you will be better equipped to save money and use the right tool for the job.

Have further questions about this subject?

Head over to Boshart's Knowledge Base: technical product information, guidelines, and more.

SHARE