It’s not easy to see the difference, but it's easy to understand what the difference is between a Standard Check Valve and a Quiet Check Valve, it’s right there in the name. If you hear a loud noise every time you pump stops, you have a Standard Check Valve installed. That noise is the check valve closing which creates a slamming effect when the water flow reverses in the discharge pipe after the pump stops. If you have never noticed it before you most likely have a Quiet Check Valve installed.

Let’s take it a step further and get educated on the benefits that come with installing a Standard Check Valve vs. a Quiet Check Valve, which will make it easier to know what is best for you and your home.

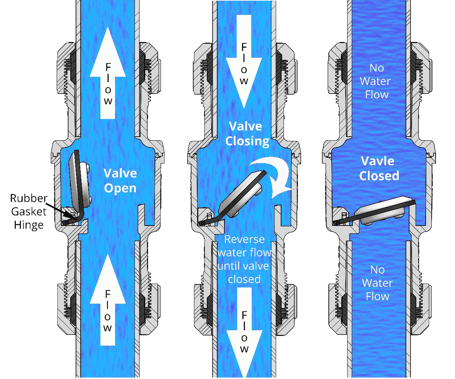

What is a Standard Sump Pump Check Valve?

A Standard Check Valve provide reliable back flow protection for your sump and sewage pump installations. Designed with an angled seat reducing the distance the flapper travels from the open to closed position. Significantly reducing the force at which the flapper contacts the seat when closing. The angled seat design shortens the travel distance of the flapper minimizing flow reversal, noise and potentially damaging hydraulic shock (water hammer). This coupled with corrosion resistant non-metallic components, results in a long-lasting reliable valve.

The below diagram illustrates the gravity closing action. As you can see, there would be some flow reversal when the pump stops, until the poppet travels to the full closed position.

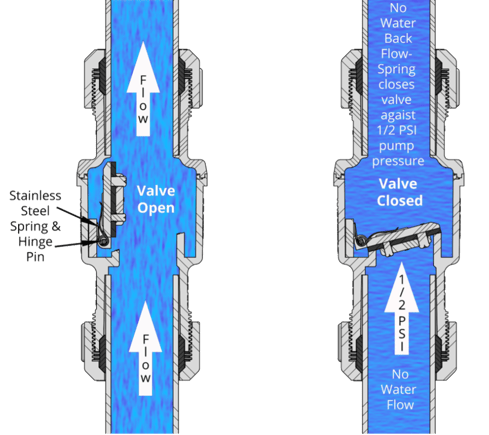

What is a Quiet Sump Pump Check Valve?

A Quiet Check Valve is a great solution when extremely quiet operation is desired. Quiet Check Valve offer all the features as the standard check valve, with the addition of a spring-loaded hinged flapper mechanism which forces the flapper to fully close against fluid flow as the pump shuts down. This rapid closing action against pressure before any flow reversal can occur, eliminates noise caused by hydraulic shock (water hammer).

Below, you can see that the spring assisted closing action shows that there is no flow reversal when the pump stops. The poppet travels to the full closed position before the water flow fully stops.

Hydraulic Shock / Water Hammer: Water in motion is forced to stop or change direction suddenly.

The industry has different types of check valves that are offered in a Standard series & a Quiet series. They are an excellent choice for Sump, Sewage and Grinder pump applications.

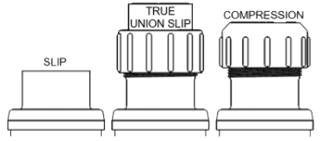

- Swing Check Valves: Available in Slip, Slip with Union & Compression Connections. Slips connections are also referred to as socket or solvent weld connections.

- PVC Solvent Weld Swing Checks: same as PVC Compression Swing Check, but with solvent weld ends. Available in Slip Connections.

- Ball / Swing Combination Check Valves: has a shut off valve allows for wastewater pumping applications combining both an in-line shut off and back flow prevention, resulting in a more compact installation. Ideal where space is limited. Available in Slip, Slip with Union & Compression Connections.

It really comes down to personal preference

The Standard Check Valve comes with some vibration when the pump cycles and is corrosion resistant. Giving you a longer lasting check valve and the peace of mind that you can hear your sump pump working.

The Quiet Check Valve has a spring-loaded hinged flapper mechanism which eliminates noise, giving you a quiet sump pump. Giving you a quiet home any time of the day, morning and night.

The Choice is yours.

Just remember either one will protect & efficiently run your pump and is a reliable back-flow prevention to your sump and sewage pump installations.

For more information, check out our Ultimate Sump and Sewage Check Valve overview page or head to our knowledge base articles.

Have further questions about this subject?

Head over to Boshart's Knowledge Base: technical product information, guidelines, and more.

+SCV(Q).jpg?width=485&name=CVSCV(Q)+SCV(Q).jpg)

SHARE