Have you ever noticed that hydrant tees and elbows have a raised pod? These raise pods are referred to as boss, and they are intentionally designed this way. The raised pod comes into play and is essential in the installation process. Hydrant tees and elbows are installed onto yard hydrants and the specific location of where they are installed requires them to have a flat edge.

In this blog, we will take a look at why hydrant elbows and tees and a have a raised pod and ensure you understand the difference between tapped and non tapped hydrant tees and elbows.

Raised Pod (Boss) on Hydrant Tees & Elbows

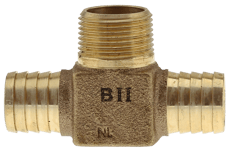

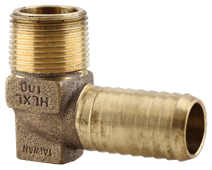

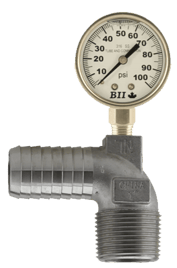

First, we should start off by pointing out what we mean by the raised pod. In the picture, you can see the smooth edge on the fitting, that is the raised pod. The hydrant tees and elbows were specifically designed with the raised pods as they provide protection for the polyethylene (PE) pipe and the stainless steel gear

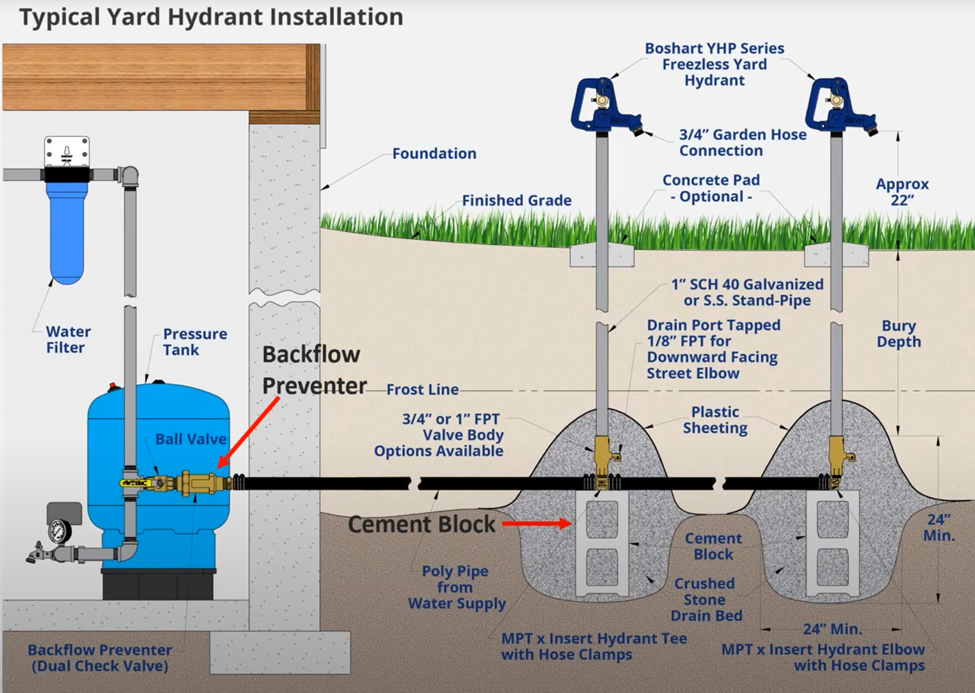

smooth edge on the fitting, that is the raised pod. The hydrant tees and elbows were specifically designed with the raised pods as they provide protection for the polyethylene (PE) pipe and the stainless steel gear  clamp bands. The raised pod rests on the cement block that is installed to support the hydrant, preventing it from settling down into the drain bed over time. The pod allows the pipe to rise and clamp up off the cement block which creates enough clearance to prevent the pipe from wear due to abrasion from the pipe rubbing on the cement block over time.

clamp bands. The raised pod rests on the cement block that is installed to support the hydrant, preventing it from settling down into the drain bed over time. The pod allows the pipe to rise and clamp up off the cement block which creates enough clearance to prevent the pipe from wear due to abrasion from the pipe rubbing on the cement block over time.

For more information regarding yard hydrants, we have a Webinar and multiple blogs. Check them out here.

Tapped vs Not Tapped Hydrant Fittings

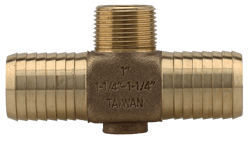

It is important to understand the difference between tapped and non tapped hydrant fittings. Tapped hydrant tees and elbows are NOT used in yard hydrant installations. You can differentiate the two because tapped fittings will have a TNL on the end of the part number. The picture on the right is an example of a tapped fitting.

because tapped fittings will have a TNL on the end of the part number. The picture on the right is an example of a tapped fitting.  Tapped tees and elbows are used in special applications, typically for installing pressure gauges in a poly piping system to monitor the system pressure. Tapped hydrant fittings can be installed in many different types of fittings, valves and accessories including, feed pump lines and for taking temperature and pressure readings. They are used to manufacture the tapped fittings due to the thick wall raised pod section which allows for the tapping of the fitting.

Tapped tees and elbows are used in special applications, typically for installing pressure gauges in a poly piping system to monitor the system pressure. Tapped hydrant fittings can be installed in many different types of fittings, valves and accessories including, feed pump lines and for taking temperature and pressure readings. They are used to manufacture the tapped fittings due to the thick wall raised pod section which allows for the tapping of the fitting.

In Conclusion

When requiring a hydrant tee or elbow, be sure to select a tapped or non tapped fitting, depending on the application for which you need it. Both tapped and non tapped fittings look similar and are available in the same materials, but as long as you pay attention to the part number and notice if there is a tapped section on the fitting, then you will be able to tell the difference.

Have further questions about this subject?

Head over to Boshart's Knowledge Base: technical product information, guidelines, and more.

SHARE