As methods evolve over time, products evolve with them to make things easier and safer. This is the case with well caps, in the past well pits were used as a way to access the connection between the well and discharge pipes. Now, the well casing extends above ground, a pitless adapter is inserted below the frost line, and the casing is topped with a well cap.

In this blog we are going to cover some terms to understand, 3 types of well caps, and some cautions to be aware of when it comes to well pits.

Prefer watching videos over reading? Check out our video above. The video delves into the same topic as the blog post!

Terms to understand

Breathing Water Well: When there are atmospheric pressure changes, air is able to enter or exit the well to prevent excess pressure or vacuum.

Vermin-proof: No small vermin or insects are able to enter the well from the cap. Well caps that are not vermin-proof have gaps between the well casing and the inside of the cap. The purpose of these gaps is to allow the well to breath but along with letting air into the well, vermin and insects have access too.

Locking: Some well caps allow for a padlock to be added to the cap. This ensures that no one without a key or code can access the well. Locking well caps use this as a tamper-proof feature.

3 Types of Well Caps

Plain

Plain well caps are the simplest type. They don't have any electrical cables that exit the well through the cap. Applications where the power supply for the pump is in a pump house or basement could use this type of well cap. Typically, they are used where jet pumps are installed on a pitless adapter.

Plain well caps are the simplest type. They don't have any electrical cables that exit the well through the cap. Applications where the power supply for the pump is in a pump house or basement could use this type of well cap. Typically, they are used where jet pumps are installed on a pitless adapter.

Conduit

Conduit well caps a re for submersible pump applications where the electric (pump) cables exit the well through the top of the well casing. They are designed with a conduit area for the cables to enter an electrical conduit on the outside of the well casing.

re for submersible pump applications where the electric (pump) cables exit the well through the top of the well casing. They are designed with a conduit area for the cables to enter an electrical conduit on the outside of the well casing.

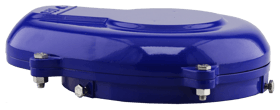

Watertight

Watertight well caps  are similar to conduit caps in the sense that they allow for an electrical conduit. The difference is that watertight well caps are sealed all the way around the casing and conduit. Vent screens are added, usually beside the conduit, to allow the well to breath but to keep vermin out.

are similar to conduit caps in the sense that they allow for an electrical conduit. The difference is that watertight well caps are sealed all the way around the casing and conduit. Vent screens are added, usually beside the conduit, to allow the well to breath but to keep vermin out.

Cautions About Well Pits

In areas where the ground freezes it's important to move water below the frost line to ensure year round water. Well pits used to be the way to go, because that was the best way to service the fittings/connection from the well and discharge pipe. Well pits need to be large enough for a person to enter them, if they aren't properly sealed at the top that means that animals or debris could fall into the well pit.

In the 1970s Mel Boshart was ahead of the times, introducing pitless adapters to the Canadian water well industry as he saw the risks with traditional well pits.

Sanitation Concerns

To block off the conduit in well pits, usually a well seal is used. These well seals include an air vent to allow the well to breathe. Contaminated surface water can enter the well through this air vent, seeping down and mixing with well water. This contaminated surface water enters the well pit through cracked cement tiles, debris falling into the pit, or poor grouting.

Repairs can be Dangerous

Getting in or out of a well pit can be dangerous as they can be 5 to 8 feet deep so a ladder might be required. Well pits may contain insufficient oxygen levels or toxic gasses.

Due to these cautions well pits are being replaced with pitless adapters and well caps. A greater understanding of well caps and the cautions of well pits will keep you and your water safe all year long.

Have further questions about this subject?

Head over to Boshart's Knowledge Base: technical product information, guidelines, and more.

SHARE