You wouldn’t think there’s a whole lot that goes into gear clamps or their installation just by looking at them, but here at Boshart we like to over-think the little things so that you don’t have to!

We’ve discussed some of the key-features of our Boshart branded gear clamps in our webinar and some questions came up. In this blog, we will answer the four questions we’ve gotten that we feel deserve a bit of extra attention.

1. How do I tell which size of clamp is right for the job?

The first thing to know when sizing a gear clamp is that your measurements should always include a ½ inch tail piece. This piece extends outside of the housing, ensuring the clamp can open the appropriate amount for easy installation. It is also important to ensure you’re measuring the outer diameter of the pipe you’ll be using. Based on the minimum and maximum opening diameters listed for each gear clamp in the catalog, you would want the diameter of your pipe to fall somewhere in the middle of those tolerances.

inch tail piece. This piece extends outside of the housing, ensuring the clamp can open the appropriate amount for easy installation. It is also important to ensure you’re measuring the outer diameter of the pipe you’ll be using. Based on the minimum and maximum opening diameters listed for each gear clamp in the catalog, you would want the diameter of your pipe to fall somewhere in the middle of those tolerances.

An important thing to keep in mind with poly pipe is that although the inner diameter is controlled, the outer diameter can vary quite a bit, depending on the density of your pipe. In addition to the traditional 75 and 100 psi low-density pipes, there are now medium and high-density variants that will have differing outer diameters.

2. How much should a clamp be tightened (in terms of lbs/inch)?

Using a nut driver, the typical force that someone can apply is in the range of 40-45-lbs/inch. This is often enough to seal poly pipe, so it doesn’t need to be much more than that. However, for rubber couplings, 60-lbs/inch of torque is required. So anywhere from 40-60-lbs/inch is required. Boshart recommends tightening all clamps to 60-lbs/inch.

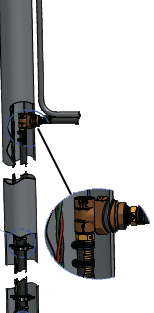

3. Why does the band on the Boshart 87 clamp series twist when tightened, when the breeze clamp does not?

Without specifics, it’s difficult to answer this question definitively. However, if you are experiencing something like this when tightening your gear clamp, a simple answer is that you may be over-tightening your screw.

something like this when tightening your gear clamp, a simple answer is that you may be over-tightening your screw.

When running our gear clamps through the QA process, we did notice that when over-tightened, the screw did start to twist downward. This was visible at torque pressures of around 150-160-lbs/inch which are far above the required torque ratings recommended for these screws/clamps. If this is something you are experiencing, you may be over-torqueing your gear clamp. At these pressures, we would be seeing other clamps breaking.

4. Should I be using more than one gear clamp per-hose?

If you are referring to double-clamping, this is never a bad idea. In most applications, using multiple gear clamps isn’t necessary, however in applications such as installing a submersible pump with poly pipe, we do recommend this as a safe practice.

If you are referring to double-clamping, this is never a bad idea. In most applications, using multiple gear clamps isn’t necessary, however in applications such as installing a submersible pump with poly pipe, we do recommend this as a safe practice.

When double-clamping, it is important to use an extra-long insert fitting that will allow for both gear clamps to be installed correctly. Doing so will give your application added protection and pull-off resistance.

Another application where this may be prudent is when dealing with buried connections and other projects where your clamps will no longer be accessible after installation. Double-clamping in this situation gives you added insurance and peace of mind that your clamps will weather the 20-50 year timeframes needed for those types of jobs.

For above-ground applications, double-clamping isn’t a bad idea, but a second clamp shouldn’t be necessary if your gear clamps are installed correctly.

In Conclusion:

We hope we were able to answer your questions regarding gear clamps and that you found this blog helpful and informative! If you have a question that we didn’t address in this post that still needs answering, please feel free to get in touch with us via email or call your inside sales representative directly at 519-595-4444 or 1-800-561-3164. We will be happy to help you out.

Have further questions about this subject?

Head over to Boshart's Knowledge Base: technical product information, guidelines, and more.

SHARE