When the pressure rating goes up, the temperature goes down, when the temperature goes up, the pressure rating goes down. This is the main thing to keep in mind when working with temperature and pressure ratings as it will help with confusion. We created a Webinar that was designed to help squash any confusions and help you feel more confident when looking at temperature and pressure ratings.

During the Webinar, any questions that came up were answered by our technical team. In this blog, we have listed the 5 questions that came up and their answers to provide you with a guide that can be quickly accessed.

For a reminder on what was discussed during the Webinar, Temperature and Pressure Rating 101: Understanding the Difference, check it out here.

Prefer watching videos over reading? Check out our video above. The video delves into the same topic as the blog post!

Questions & Answers

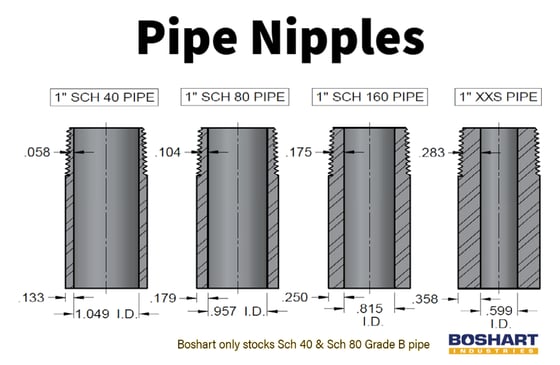

1. Your pipe nipples are manufactured from Grade B pipe, are there higher quality Grade A pipe nipples available?

The difference between Grade A and B pipe is not a quality issue but rather the intended application. ASTM A53 Grade B pipe is more popular than other grades of pipe as it is manufactured from steel which has a higher carbon content resulting in higher tensile and yield strength. Grade B having higher stress values is better suited for machining operations and is used for pipe nipples. Grade A pipe is a softer steel and is typically used for special applications such as cold bending and close coiling since it is much easier to bend.

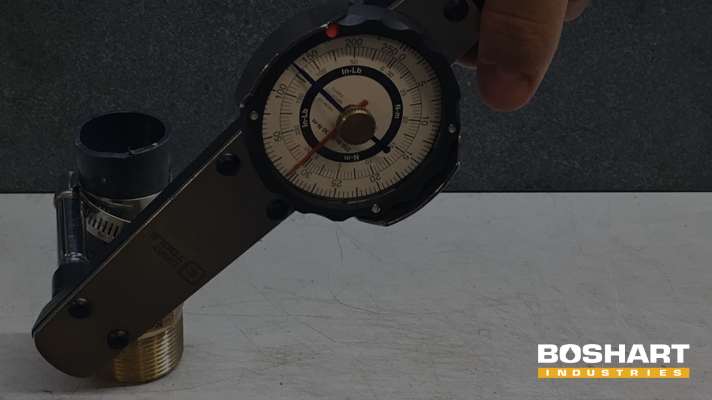

2. Can I run slightly over the published pressure rating of the valve?

The operating pressure should be non shock and within the limits listed in the pressure temperature chart as found on the product datasheet.

3. What do you mean when you mention non shock pressure rating?

Non shock pressure is the maximum pressure that a valve or fitting can be subjected to. If a systems pressure could potentially exceed the non shock rating due to pressure surges or water hammer, the valve is not suitable and you will need to select a valve or fitting with a pressure rating which is over and above the anticipated pressure. Water hammer can occur when a valve is closed too quickly. Happens most commonly on 1/4" turn ball valves on dishwashers and washing machines. For more information on water hammer, check out our blog, Taking a Look at Check and Foot Valves.

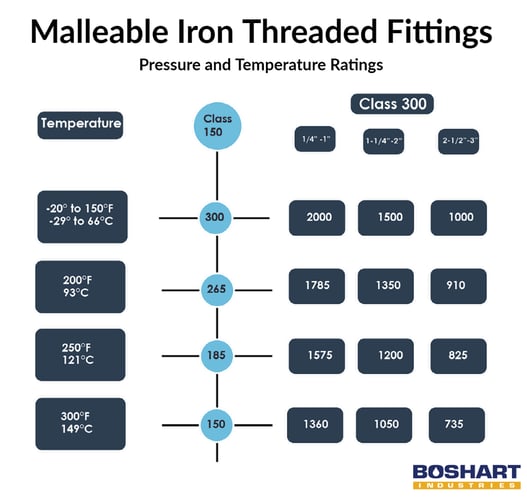

4. To confirm, malleable fittings rated for 300 psi could be a class 150 fitting?

A class 150 fitting is rated for 300 PSI as long as the operating temperature does not exceed 150 F°. Jobs could be lost due to quoting the more expensive heavy pattern class 300 malleable. If the specifications call for a malleable fitting rated for 300 PSI, the winning tender would of quoted the less expensive class 150 fitting since the operating temperature was less than 100 F°. If the description is in PSI or pounds and does not clearly state the class, one needs to clarify the class to be sure the right fitting is being quoted.

5. If the G designation gas in WOG refers only to any non-flammable gaseous fluids, does the O for oil cover petroleum products?

The same applies as with gas designation which does not imply a product suitability or third-party approval for use of flammable gases. Similarly, the O designation for oil does not imply product suitability or third-party approval for use with any petroleum products.

In Conclusion:

With the help of these questions, answers and Webinar, you will have the knowledge to successfully choose the appropriate class fittings required for your job, hopefully saving you a headache and some money. If you ever run into any other issues or questions when working with temperature and pressure ratings, please reach out and we will be happy to help.

Have further questions about this subject?

Head over to Boshart's Knowledge Base: technical product information, guidelines, and more.

SHARE