Connection types can be overwhelming. There are several different types of connections and in some cases they can be very similar to one another. In this blog, we are going to explore the different connection types you may come across and highlight the difference between each one.

So before you pull your hair out due to frustration and confusion, dive in with us. We will make it simple for you, saving you and your hair.

Connection types can be found with multiple combinations of connections sometimes making it difficult to tell which end is which. We have included pictures for a visual aide to ensure you can tell the difference between the various connection types.

We are covering the below connection types:

- Threaded

- Barbed / Insert

- Mini Barb / Poly Barb

- Combination Nipples / Hose Menders

- Slip / Socket / Spigot

- Push-Fit

- Twist and Lock

- Plastic Quick Connect

- Flare

- Compression

- Garden Hose

- Solder / Copper

- Crimp / Cold Expansion

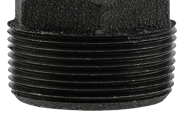

Threaded

Threads are a key component of most fittings. You have probably ran into threads a couple of times but they may not have been referred to as threading. National Pipe Thread (NPT) refers to the measuring of tapered threads on threaded pipes and fittings.

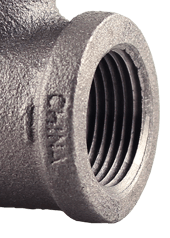

Threads are broken into two categories: Male and Female. Male threads are  found on the outside of the pipe or fitting and female threads are found on

found on the outside of the pipe or fitting and female threads are found on  the inside. More commonly male and female threads are referred to as MPT and FPT.

the inside. More commonly male and female threads are referred to as MPT and FPT.

Now, you may have seen another term, Iron Pipe Size (IPS) represented as Male Iron Pipe (MIP) and Female Iron Pipe (FIP). Fun fact, it means the same thing as MPT and FPT. Once you know they are virtually the same, it makes it much easier when looking for the connections you need.

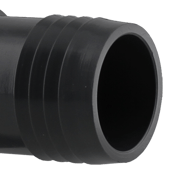

Barbed / Insert

If thread is a key component to a fitting then so is barbed. As seen in the pictures, it is easy to differentiate between barbed and threads. Don't know the term barbed, maybe you've heard of Insert? Barbed and Insert are the same. Some people call them barbed fittings and some people call them Insert. Both are correct. Barbs are inserted into tubing and because of their d

If thread is a key component to a fitting then so is barbed. As seen in the pictures, it is easy to differentiate between barbed and threads. Don't know the term barbed, maybe you've heard of Insert? Barbed and Insert are the same. Some people call them barbed fittings and some people call them Insert. Both are correct. Barbs are inserted into tubing and because of their d esign, they stay in place better.

esign, they stay in place better.

The barbed connection on fittings does not always look the same between every part you will see. Barbs can be large or small or more spaced out depending on the fitting and what it is made to be used for.

Mini Barb / Poly-Barb

Mini Barb, sometimes referred to as Poly-barb, connect to polyethylene tubing and have excellent vibration resistance. They come in smaller sizes than regular barbed fittings.

Combination Nipples / Hose Menders

Combination nipples are used to transition from hose to pipe or valves. Hose menders are used to connect two lengths of hose together or repair a section of hose that has been damaged. Combination nipples and hose menders are good to be used with thermoplastic and natural rubber straight end hoses. The barbs on these fittings are specially designed for those applications.

Slip / Socket / Spigot

Slip /Socket connections can be found in Sch 40 and Sch 80 PVC fittings. Slip is considered the "female" connection of PVC fittings and can also be known as the hub. Slip /Socket allows for the spigot end to be inserted.

Slip /Socket connections can be found in Sch 40 and Sch 80 PVC fittings. Slip is considered the "female" connection of PVC fittings and can also be known as the hub. Slip /Socket allows for the spigot end to be inserted.

Spigot is to be inserted into a slip /socket connection typically using glue to secure the connection. Spigot is considered the "male" connection of PVC fittings. The end of the spigot has the same outside diameter as pipe.

As you can see in the picture, slip / socket is the top connection and spigot is the bottom connection.

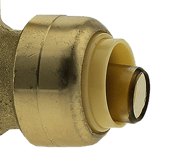

Push-Fit

Push-fit connections can be found on fittings and ball valves. They are mainly used to connect Copper Tube Size (CTS) CPVC or PEX. CTS is a much smaller tube size than NPT which means NPT pipe can’t be used in a Push-fit connection. The connection is made by simply pushing the tube over the tube support into the connection. A special disconnect tool can be used to disconnect the tubing and fitting allowing it to be reused.

Twist and Lock

Twist and lock connections are a combination of push-fit and compression technology. They have the ability to lock into place by twisting the locking nut clockwise allowing them to tightly secure to tubing. This is where the name Twist and Lock comes from.

Twist and lock connections are a combination of push-fit and compression technology. They have the ability to lock into place by twisting the locking nut clockwise allowing them to tightly secure to tubing. This is where the name Twist and Lock comes from.

Plastic Quick Connect

Plastic Quick Connect fittings are very similar to the Push-fit fittings. Similar, but not the same. Tubing gets pushed into the fittings socket until the end of the tube hits the tube stop and then the connection is tight and secure.

Flare

Flare connections are commonly found on, you guessed it, Flare fittings. The thread on flare fittings does not reach to the end of the fitting as seen in the picture. Flare is a type of compression fitting and they are used most commonly with metal tubing. You will most likely only run into female flare or male flare when referring to connectors.

Flare connections are commonly found on, you guessed it, Flare fittings. The thread on flare fittings does not reach to the end of the fitting as seen in the picture. Flare is a type of compression fitting and they are used most commonly with metal tubing. You will most likely only run into female flare or male flare when referring to connectors.

Compression

Compression connections are commonly found on Compression fittings. Are you seeing a pattern here? As seen in the picture, they are made up of three separate pieces. As you tighten the nut, there is pressure put on the sleeve securing the connection. They are used in plumbing systems to join tubing together like copper or polyethylene. Compression could sometimes be introduced as CP.

Compression connections are commonly found on Compression fittings. Are you seeing a pattern here? As seen in the picture, they are made up of three separate pieces. As you tighten the nut, there is pressure put on the sleeve securing the connection. They are used in plumbing systems to join tubing together like copper or polyethylene. Compression could sometimes be introduced as CP.

Garden Hose

Garden Hose Thread (GHT) comes male (MGHT) and female (FGHT). It's important to note that GHT is different from NPT. Garden hose connections are not compatible with NPT even though both are threaded. Where a water hose fitting is required, this would be the connection to look for. You can see in the picture that the top connection is MPT and the bottom connection is MGHT.

Solder / Copper (C)

Solder / Copper (C)

In the past this was a very common connection, but is not as popular anymore. Due to the risks that go with the soldering process. Copper pipe is inserted into the fitting and solder fills the gap between the fitting and the pipe.

Crimp / Cold Expansion

Crimp and cold expansion connections are good for use with pex tubing. The pipe is crimped onto the fitting using a specific tool. This is done by adding a crimp ring onto the tubing. The ring interacts with the ribs on the fitting to secure the connection.

Crimp and cold expansion connections are good for use with pex tubing. The pipe is crimped onto the fitting using a specific tool. This is done by adding a crimp ring onto the tubing. The ring interacts with the ribs on the fitting to secure the connection.

Similar to the crimp connection, cold expansion uses a specific "ring" to tighten the connection, only it is generally referred to as the sleeve. The connection is made by placing the sleeve on the pex tubing, expanding the sleeve, then inserting the fitting. Giving the sleeve and tubing time to shrink back to it's original size creates a very secure connection.

Have further questions about this subject?

Head over to Boshart's Knowledge Base: technical product information, guidelines, and more.

SHARE