Heat Shrink Kit or Splice Kit? Both are correct, they are actually the same! Splice kits are typically referred to as heat shrink kits as they require a heat source to form the secure connection. Heat shrink kits may be small but they protect wire indoors or outdoors.

In this blog, we walk you through exactly what a heat shrink kit is, squash a common misconception, and take a step by step look at how to properly install them. To avoid confusion, we will be referring to them as heat shrink kits throughout the post. Let's take a look!

Prefer watching videos over reading? Check out our video above. The video delves into the same topic as the blog post!

What are Heat Shrink Kits?

Heat Shrink kits are electrically insulated and protect wires, electrical components, and other objects. They also provide a seal that prevents liquid and solid contaminants from reaching any sensitive components. Heat shrink tubing is a mechanically expanded plastic tube usually made of polyolefin but can be made of other materials like PVC. Heat shrink tubing is designed to insulate wires, providing abrasion resistance and protection from environmental harms for stranded and solid wire conductors, joints and connections in electrical engineering.

Heat Shrink kits are electrically insulated and protect wires, electrical components, and other objects. They also provide a seal that prevents liquid and solid contaminants from reaching any sensitive components. Heat shrink tubing is a mechanically expanded plastic tube usually made of polyolefin but can be made of other materials like PVC. Heat shrink tubing is designed to insulate wires, providing abrasion resistance and protection from environmental harms for stranded and solid wire conductors, joints and connections in electrical engineering.

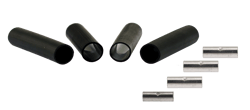

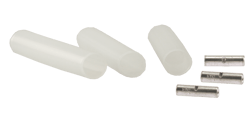

They can also be used to repair any insulation on wires or to bundle the wires together to protect the  wires from minor abrasion. Polyolefin tubes are the most common type of tubing for heat shrink kits. They have a continuous use temperature of 55° to 135° C and are extremely flexible and fast shrinking. Polyolefin tubing is manufactured in a wide range of colours including clear. Black tubing is recommended the most for outdoor applications. Typical applications for polyolefin tubing are electrical insulation, abrasion protection, and strain relief.

wires from minor abrasion. Polyolefin tubes are the most common type of tubing for heat shrink kits. They have a continuous use temperature of 55° to 135° C and are extremely flexible and fast shrinking. Polyolefin tubing is manufactured in a wide range of colours including clear. Black tubing is recommended the most for outdoor applications. Typical applications for polyolefin tubing are electrical insulation, abrasion protection, and strain relief.

Applications

Although heat shrink tubing is very popular in electrical applications, they are also commonly used to bundle loose items, mechanical protection from abrasion or cutting, cushioning from impact, thermal insulation, and protection from environmental moisture or UV light.

Depending on the material that the heat shrink is made from, there are two ways the heat shrink tubing will work. Some materials will shrink the volume of the material, while other materials could cause the heat shrinks to expand. The original inside diameter of the heat shrink tubing needs to be large enough to slip over whatever needs to be covered, then the tubing is "shrunk" onto the component by heating the tubing using a heat gun, flow through oven or any other thermal energy heat source. Always be cautious when heating the tubing, heat shrink tubing can melt or catch fire just like any other plastic.

For a closer look at how heat shrink kits are used in a submersible pump installation, check out our blog Components of a Typical Submersible Pump Installation.

Proper Storage

Be sure to properly store your heat shrink kits. Any UV exposure can degrade the properties. A quick inspection of the product is a good indication of whether the heat shrink tubing sustained any damages due to poor storage conditions. To confirm the heat shrink tubing is not damaged before use, check if the tubing has discoloured, stiffened or gummy on the surface. Shelf life concerns are not for all materials, polyolefin tubing normally has a greater ability to withstand high storage temperatures.

Myths

A common misconception that surrounds heat shrink tubing is that the tubing shrinks. To squash the myth, the heat shrink tubing does not actually shrink. The tubing is mechanically expanded and holds the expanded diameter until heated, then the tubing simply returns to its original diameter.

Installation Instructions

- Strip 1/4" insulation from the cable and motor wires

- Remove any grease from the wires

- Slide heat shrink tube over one end

- Insert wires into the wire connector

- Crimp to attach the wire connector to the wires

- Pull lightly to ensure the crimp is secure

- Centre the tube over the wire connector

- Use low heat, shrink tube from the centre, out

- When it is completely sealed, a slight glue amount should be visible

- Let cool for a couple of minutes

Heat shrink kits have many uses and are very important. They play a vital role in submersible pump installations but can also be used in other applications. The installation instructions will ensure a smooth and quick process, with hopefully no headaches.

Have further questions about this subject?

Head over to Boshart's Knowledge Base: technical product information, guidelines, and more.

.png)

.png)

SHARE