Have you ever picked up an insert fitting and noticed that the barbs seem just a bit larger than the inside diameter of the poly pipe you’re working with? It’s not a design flaw, it’s intentional, and there’s a very good reason behind it. This principle holds true no matter what material you’re using, whether it’s zinc-plated steel, brass, bronze, stainless steel, nylon, poly, or PVC.

In this blog, we’ll break down why insert fitting barbs are designed with slightly larger diameters and what that means for you.

This BoshartU blog is based off of our Knowledge Base article, Why do Insert Fittings for Poly Pipe (PE) have Barbs slightly Larger Diameters that the I.D of the Pipe? Read it here.

Larger Barbs? Why?

The main reason for the barbs having a larger diameter is due to the semi-rigid nature of poly pipe. Standard gear hose clamps of any make or brand are not designed to provide enough pressure that is required to squeeze poly pipe beyond its original extruded I.D. Which means that the only solution is the poly pipe must be stretched over the barb. This is often done by heating the poly pipe. You can simply dip the end of the pipe in warm water to make it more pliable.

poly pipe. Standard gear hose clamps of any make or brand are not designed to provide enough pressure that is required to squeeze poly pipe beyond its original extruded I.D. Which means that the only solution is the poly pipe must be stretched over the barb. This is often done by heating the poly pipe. You can simply dip the end of the pipe in warm water to make it more pliable.

When the insert fittings are inserted into the poly pipe, the poly pipe will return to its extruded size, just like a rubber band. The worm gear hose clamps assist the poly pipe in returning to its original size by applying pressure onto the poly pipe, making a water tight seal while also providing a pull off proof connection.

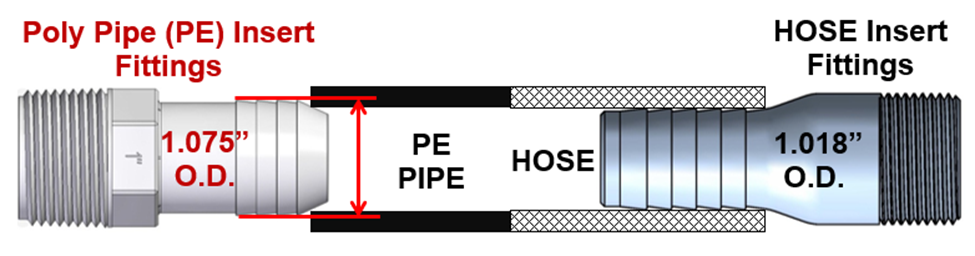

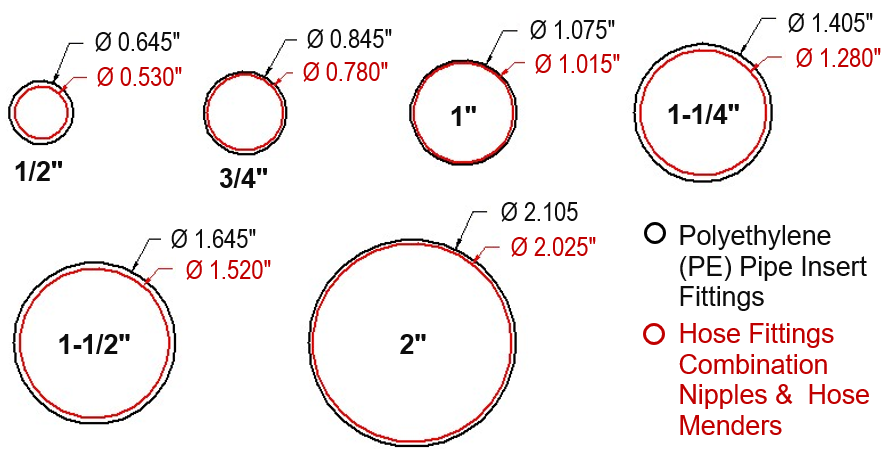

Difference between Poly Pipe Insert Fittings & Hose Insert Fittings

Hose Insert Fittings have smaller barbs. These will have a loose fit and will not grip in the poly pipe. Since it has smoother barbs, it does allow for easy removal and reinstallation of the hose. Boshart's hose fittings are machined with a special flat area on the lead barb. This feature makes the installation into reinforced hose easier and allows for easy identification of a hose fitting from poly pipe insert fittings.

Hose Insert Fittings have smaller barbs. These will have a loose fit and will not grip in the poly pipe. Since it has smoother barbs, it does allow for easy removal and reinstallation of the hose. Boshart's hose fittings are machined with a special flat area on the lead barb. This feature makes the installation into reinforced hose easier and allows for easy identification of a hose fitting from poly pipe insert fittings. Caution

Have questions about Boshart products?

Head over to Boshart's Knowledge Base: technical product information, guidelines, and more.

SHARE