For years, brass tank tees have been the most popular choice for water well systems. This is because brass was always the more economical metal and most pressure tanks had brass connections. Recently, it's been an increasing trend that many pressure tanks have been re-designed to include a stainless steel connection instead of brass. This switch will naturally spark an increase in the popularity of stainless steel tank tees.

But why can't you use your brass tank tee with a stainless steel connection? You may or may not be aware but connecting dissimilar metals is not recommended.

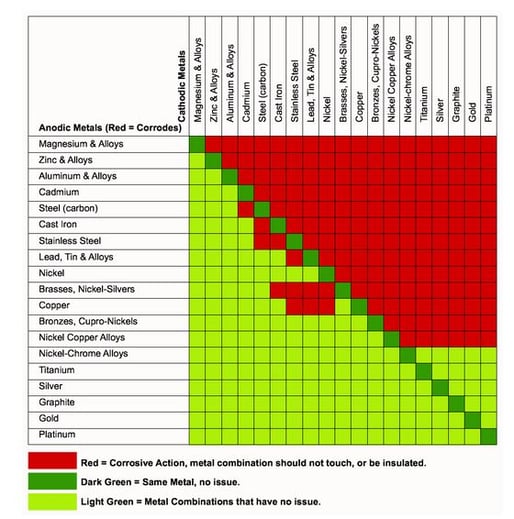

Dissimilar metals are metals and alloys that have extensively different properties. When dissimilar metals come in contact, galvanic corrosion can occur.

Below, we have listed the most common materials for tank tees and why it's important you use the right material for your system.

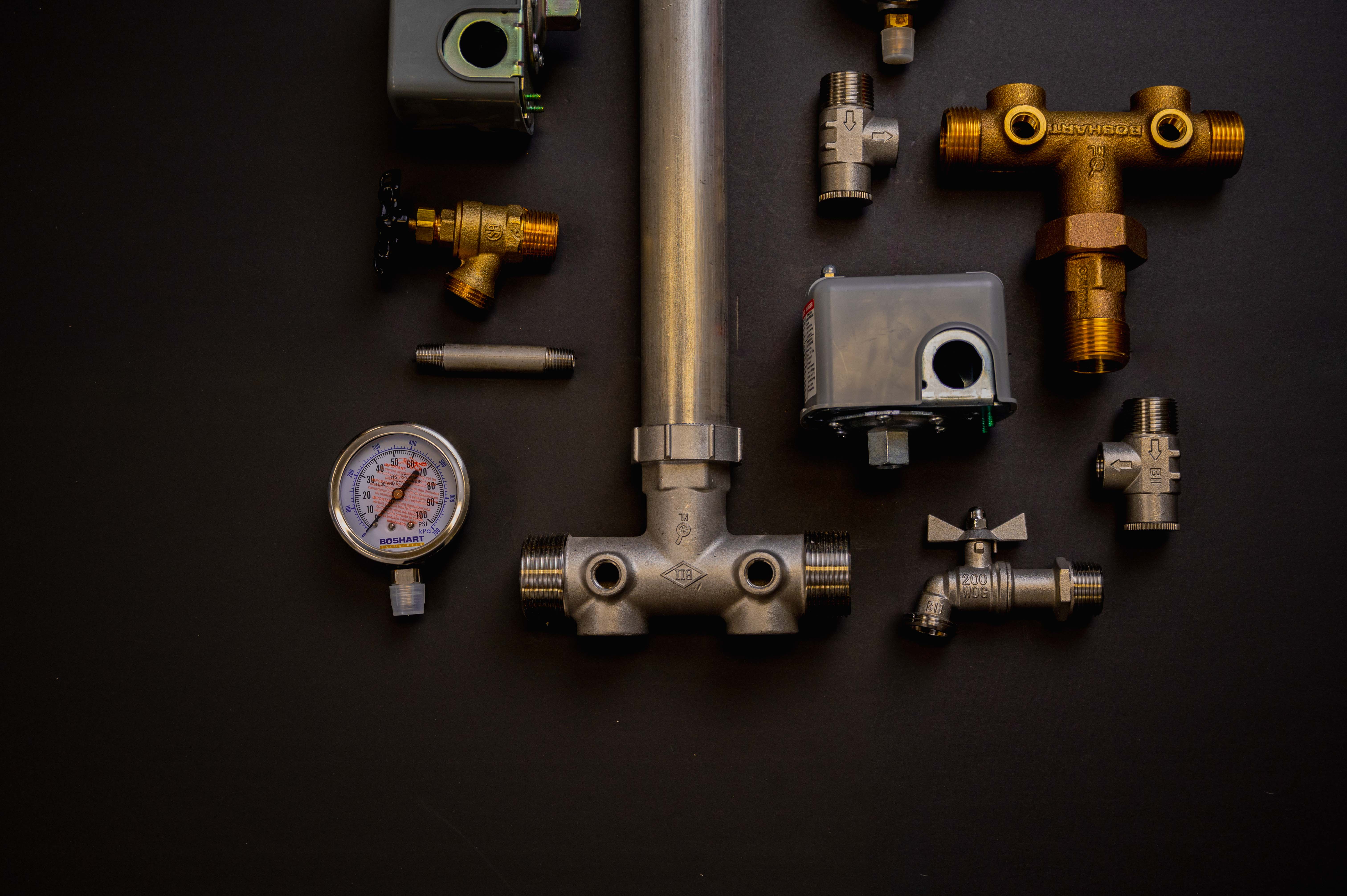

Variety of Materials

There are four common materials that tank tees are available in: Stainless Steel, Brass Alloy, Galvanized and PVC.

Stainless Steel

As a material, stainless steel has become more economical over the last couple of years (although not necessarily always true in tank tees specifically), and stainless steel tank tees are slowly becoming more popular. They are typically cast from 304 stainless steel which is extremely durable and very corrosion resistant.

Unlike brass tank tees, stainless steel tank tees do not contain zinc which could cause dezincification in brass tank tees when being used with aggressive water conditions. Stainless steel tank tees also have a high strength tolerance, eliminating any risk of stress cracking when threading into a female connection.

Like mentioned before, with the shift of tank tees including stainless steel connections, the choice between stainless steel or another material is fairly simple. If you don't want to run any risk of galvanic corrosion, sticking with the similar metal is always advised.

Brass Alloy Tank Tees

Brass Alloy Tank Tees

Brass, as a material, is softer and much easier to obtain a leak free connection with no issues of galling. Currently, brass alloy tank tees are less expensive compared to stainless steels and are suitable for installation in most areas.

One downside of brass alloy tank tees are they are not as corrosion resistant as their stainless steel counterparts. If installing in areas where the water is known to be highly corrosive, it is recommended to choose a stainless steel tank tee in order to protect from these issues.

Galvanized Tank Tees

Compared to stainless steel and brass, galvanized tank tees are the cheaper option. Typically, galvanized tank tees are limited to installations on galvanized pressure tanks without a bladder and are usually selected to eliminate the risk of galvanic corrosion between dissimilar metals when being used with galvanized nipples and fittings.

galvanized tank tees are limited to installations on galvanized pressure tanks without a bladder and are usually selected to eliminate the risk of galvanic corrosion between dissimilar metals when being used with galvanized nipples and fittings.

Important Note: some plumbing codes do not allow the use of galvanized nipples and fittings. You must verify that the galvanized tank tees meet the applicable plumbing code requirements before installing.

PVC Tank Tees

PVC tank tees are a very competitive option compared to the above materials. PVC tank tees are extremely resistant to corrosion and are a suitable alternative to metal alternatives. They are not as durable as metal tank tees and there are not near as many configurations available.

PVC tank tees are a very competitive option compared to the above materials. PVC tank tees are extremely resistant to corrosion and are a suitable alternative to metal alternatives. They are not as durable as metal tank tees and there are not near as many configurations available.

PVC tank tees need to be installed properly with the use of a high quality thread sealant paste rather than PTFE thread sealant tape and be sure to avoid over-tightening. If overtightened, PVC tank tees are much more susceptible to cracking than those of galvanized, brass, or stainless steel.

Dissimilar Metals

Galvanic corrosion is an electrochemical process where a metal corrodes when connected to a metal that is connected through an electrolyte.

It occurs when one metal (the cathode) is protected, and the other metal (the anode) is corroded.

Below is a chart that shows the different materials that if in contact with each other, would marginally increase corrosion.

To prevent galvanic corrosion from occurring, it is important to connect similar metals together. When working with your pressure tank, before purchasing a tank tee, it is important to find out what connection material your tank includes. This will greatly help determine which tank tee you will need.

Although stainless steel tank tees are more expensive compared to brass, if dissimilar materials are connected and galvanic corrosion occurs, the cost of needing to replace your brass tank tee will be more compared to purchasing the stainless steel tank tee in the first place. Some food for thought.

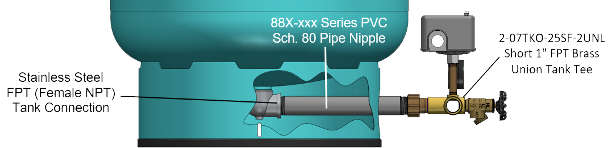

If you are wanting to use a brass tank tee, you can avoid all risk of corrosion between dissimilar metals when connecting to a stainless steel connection if you install a Sch.80 PVC pipe nipple between the tank connection and the brass tank tee. Simply, select the appropriate length of the PVC nipple with a short female union tank tee to achieve the proper CEL (center end length).

Thread Sealant

Not only is it important that you connect similar metals, it is also important to properly connect the tank tee to the connection by using the correct thread sealant, especially when working with stainless steel.

For tips and important information on how to properly seal stainless steel, check out our blog, How to Properly Seal Stainless Steel Fittings, Nipples & Well Supplies.

In Summary:

You pressure tank will provide you with all the information you need to properly select a tank tee for your system, especially letting you know what material the connection is, solidifying which material tank tee you require. This is an important step to follow to ensure you do not connect dissimilar metals, causing galvanic corrosion.

Have further questions about this subject?

Head over to Boshart's Knowledge Base: technical product information, guidelines, and more.

SHARE