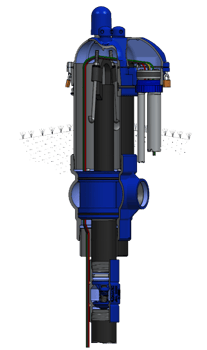

Industrial Pitless Units are built up of many parts that all play an important role in the functionality of the unit. When it comes to understanding the job of each feature, it can become confusing. When we held a webinar, some questions came up that are worth highlighting.

In this blog, we go over the four questions that arose during the Webinar and look at the answers that our technical team provided to help everyone. Let's take a look.

To remind you of the information shared during Unearth the Features of our Industrial Pitless Units Webinar, check it out here.

Questions & Answers

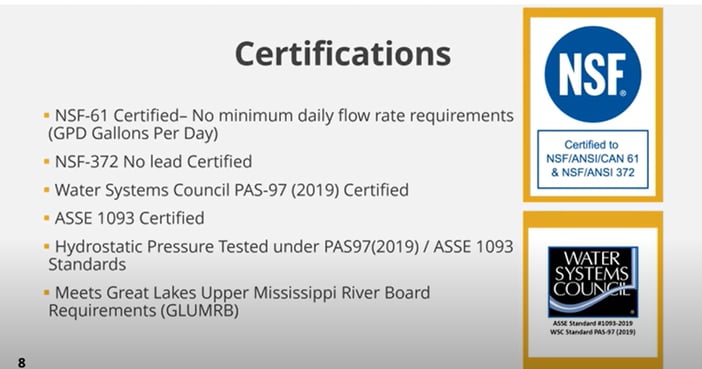

1. When talking about NSF 61 certification, what does no minimum gallons per day restriction mean?

Very few people are aware that not all NSF 61 certifications are equal. Our units have passed all standard requirements that were tested from NSF. Pitless units that fail this testing, would opt to obtain the certification with a minimum daily flow requirement tied to the level of toxins which were released. Since Boshart pitless units release no toxins, we are the only unit on the market not tied to those requirements.

NSF would calculate how much water would need to pass through the pitless unit each day to reduce the contact time between the water and the pitless unit.

More flow reduces the contact time of the contaminants to be absorbed into the water. If enough water continually passes through each day, the water will not absorb harmful levels of contaminant.

However, if the daily flow requirements are not met, the certification becomes null void meaning, if it did not produce the required volume 24/7 then the certification is invalid. For example, if the factory were to shut down for a day, it could leak contaminants that were above the allowable limits reduced and this would make the certification null void.

However, if the daily flow requirements are not met, the certification becomes null void meaning, if it did not produce the required volume 24/7 then the certification is invalid. For example, if the factory were to shut down for a day, it could leak contaminants that were above the allowable limits reduced and this would make the certification null void.

Specific raw materials were selected for castings and seals along with NSF certified epoxy coating that were all tested within the NSF 61 parameters ensuring there will be no issues even if the water remains in contact with the wetted surface area for long periods of time. To the best of our knowledge no other pitless units on the market have this certification without limited daily flow rates.

2. What is a protective sleeve and do you sell them?

The protective sleeve is simply a short piece of well casing typically, PVC casing of equal inside diameter to the well casing. PVC is preferable as it is much lighter and easier to handle as it is less likely to scratch the O-ring seating areas. Boshart does not sell the sleeves as well drillers and service companies have the casings readily available and simply cut a section to the required length for their specific bury depth.

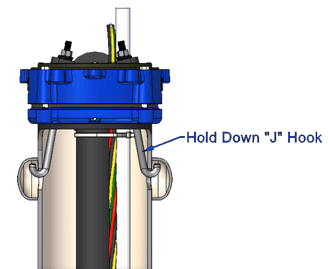

3. Why do you only offer the hold down system and not the torque arrestor feature?

In the past, we had three options available. The options were a no hold down mechanism, a torque arrestor system and a hold down hook system.

No Hold Down Mechanism

With the no hold down mechanism, we offered that to compare with our competitors and in some deep-set installations there wasn't a risk of lift out so this wasn't needed, although it did not protect against rotation from locked rotor.

Torque Arrestor

The torque arrestor option did protect against both locked rotor and lift out but the effectiveness of that was dependent on how tight the installer made the bolts on the torque arrestor. It was impossible for us to guarantee the holding force so we eliminated that option.

Hold Down System

The hold down system offers extra protection since we standardized this system, we were able to drive down the cost. The hold down hook system comes with pods on the upper barrel that prevent the straps from slipping during installation. The hooks themselves prevent against lift out and rotation because of locked rotors so it has the most safety features out of all three of the options. We made this the standard option because it means that we can drive the cost down so you get the safest option for a cost-effective price.

4. Can you better explain the assembly process of the well caps?

Our well caps do have some unique features that make them very easy to install. A key feature is that they are provided and packaged as separate

Our well caps do have some unique features that make them very easy to install. A key feature is that they are provided and packaged as separate units. The actual cover is separate from the lower ring assembly and there are positioning tabs on the lower assembly so you can simply set it on to the well casing and it'll be in perfect location. There is no need to lift the very heavy assembly on the complete units.

units. The actual cover is separate from the lower ring assembly and there are positioning tabs on the lower assembly so you can simply set it on to the well casing and it'll be in perfect location. There is no need to lift the very heavy assembly on the complete units.

In Conclusion:

Our technical team is always available to help answer any questions you may have. For more information and to take a closer look at our Industrial pitless units, check out our two blogs, Benefits of Boshart Industrial Pitless Units and Boshart vs Baker: Industrial Pitless Units.

Have further questions about this subject?

Head over to Boshart's Knowledge Base: technical product information, guidelines, and more.

.png)

SHARE